|

|

|

|

Aerodynamic and Hydrodynamic Performance |

| Performance Boat design and setup secrets for Recreational tunnels, Offshore Cats, Racing tunnels, Fishing/Utility hulls, Vee and Vee-Pad Hulls, Bass Boats | |

| Home New About Us Technical Articles TBPNews Archives FREE Downloads Research Contact Us | |

|

Testimonials

Reviews

Join TBPNews

Advertise

Search

Buy Now

|

|

|

|

|

| VBDP© Vee Pad Performance Analysis | ||

| Get complete article by email request: | Share: | |

| BREAKTHROUGH! | |||

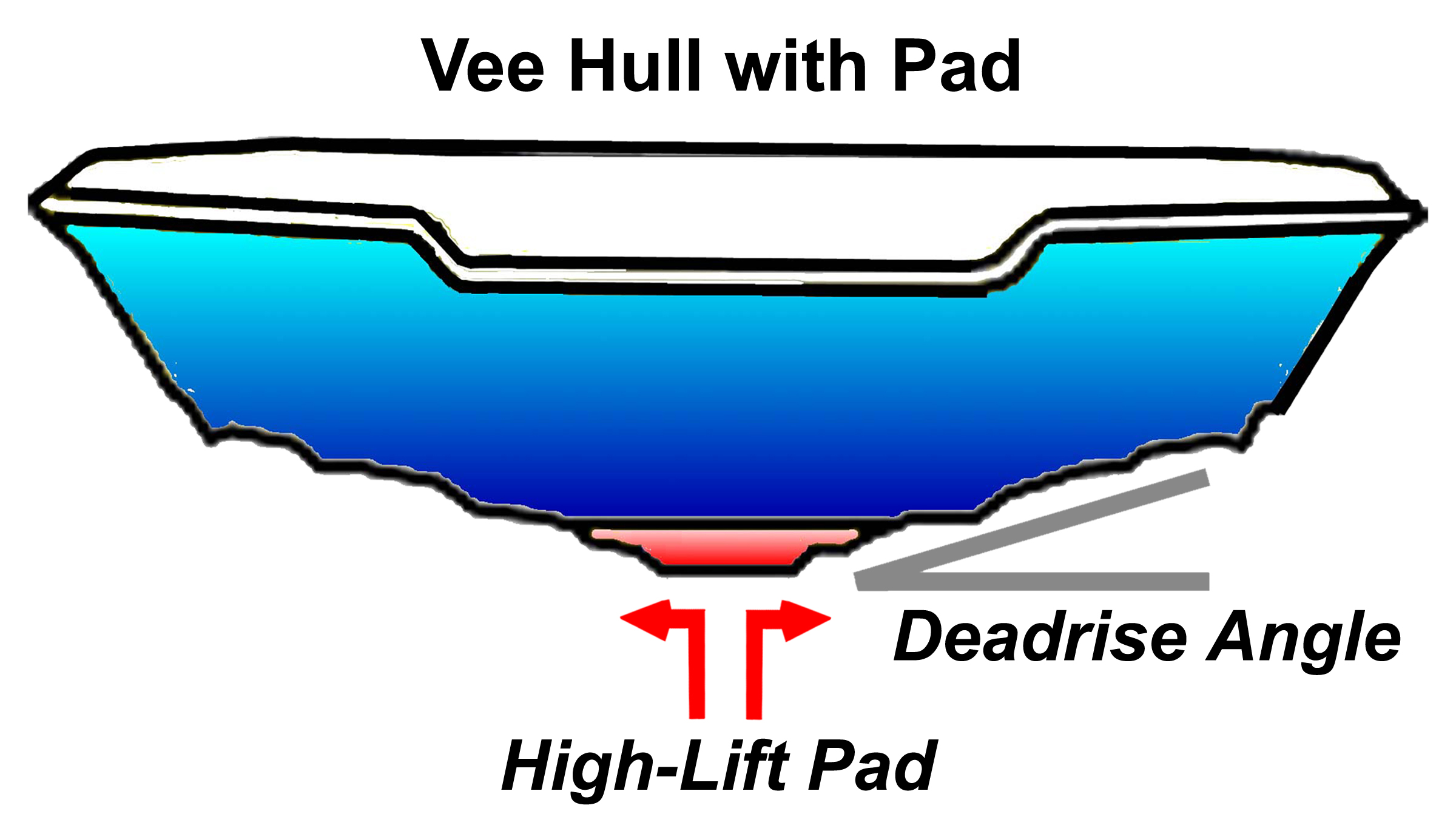

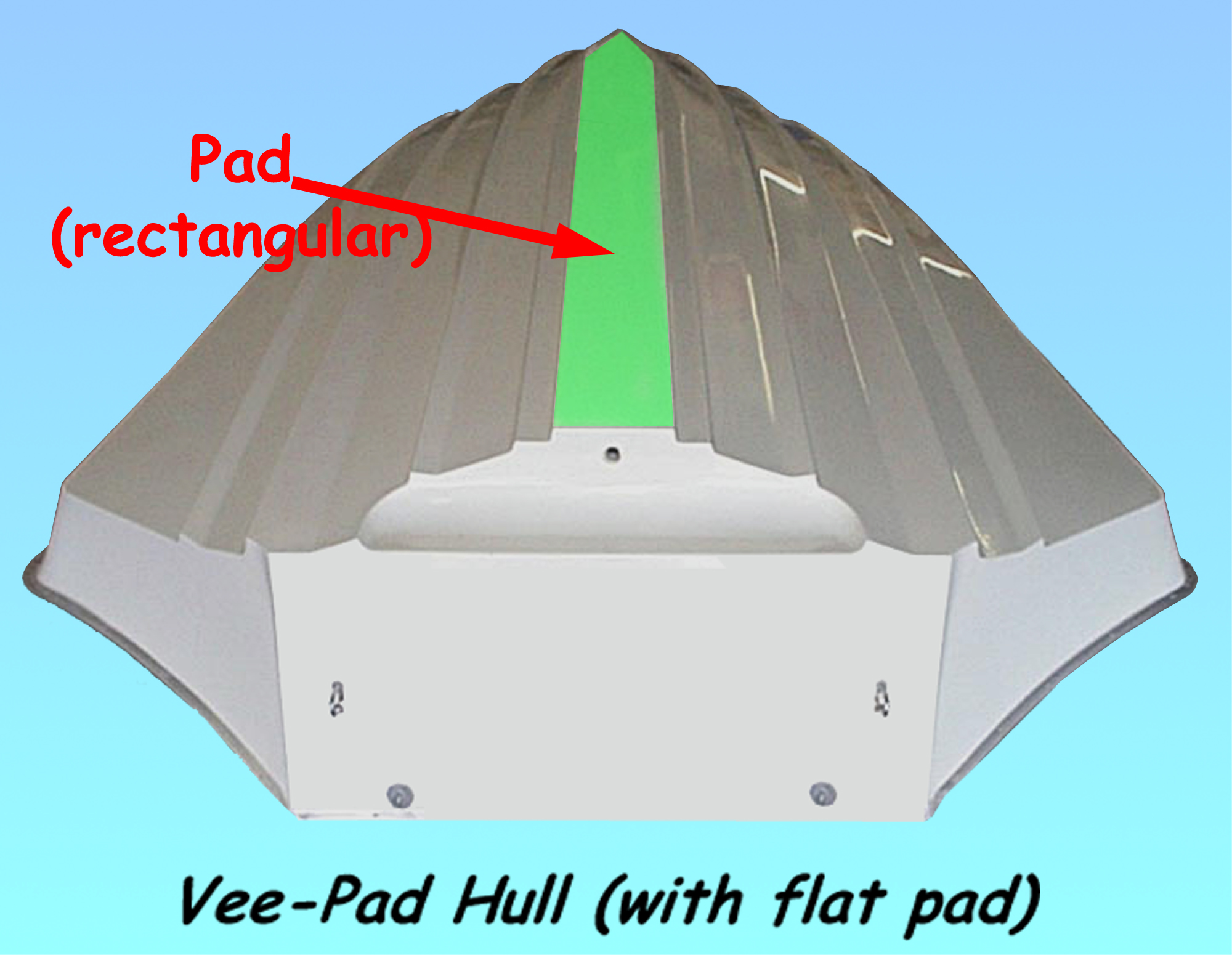

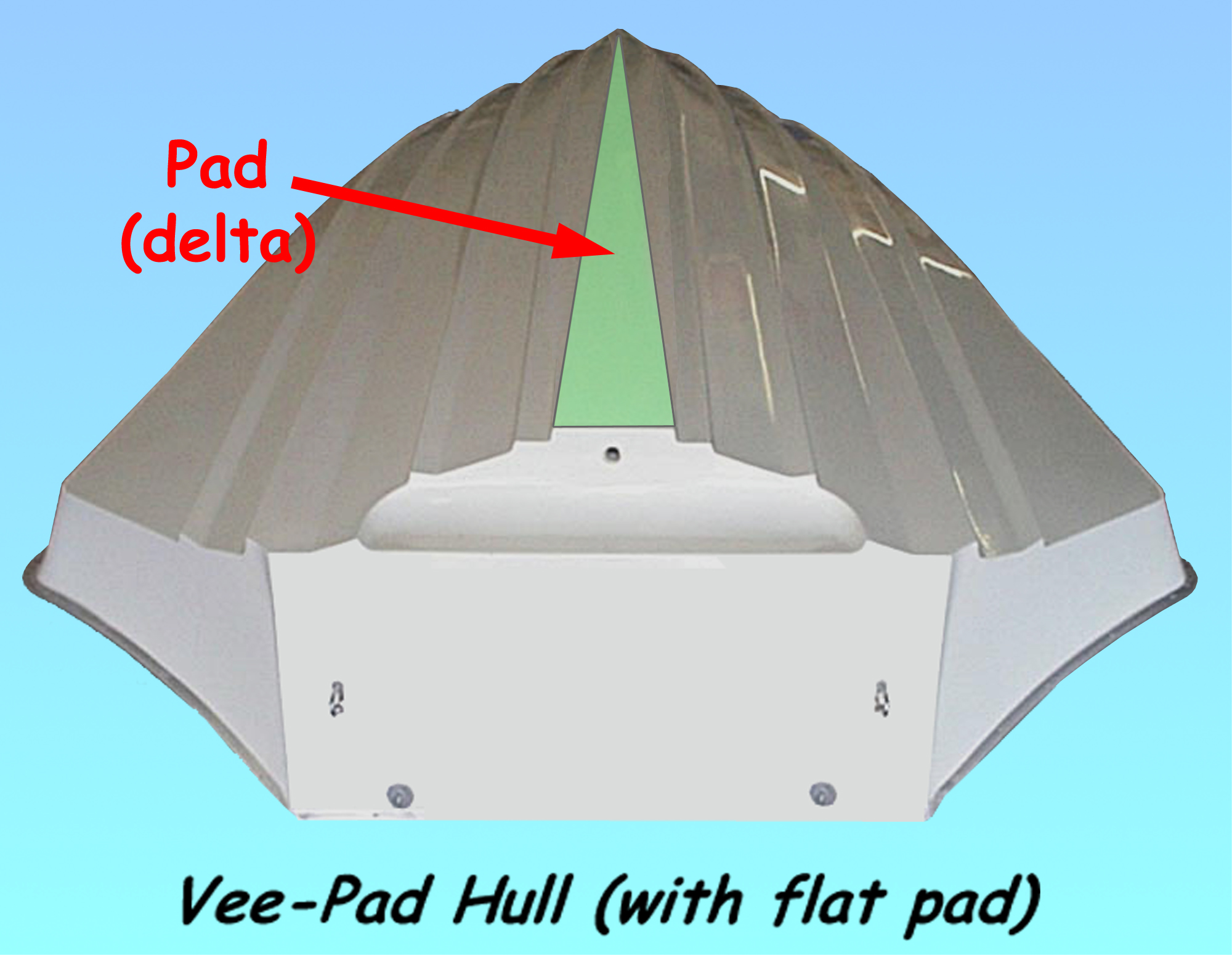

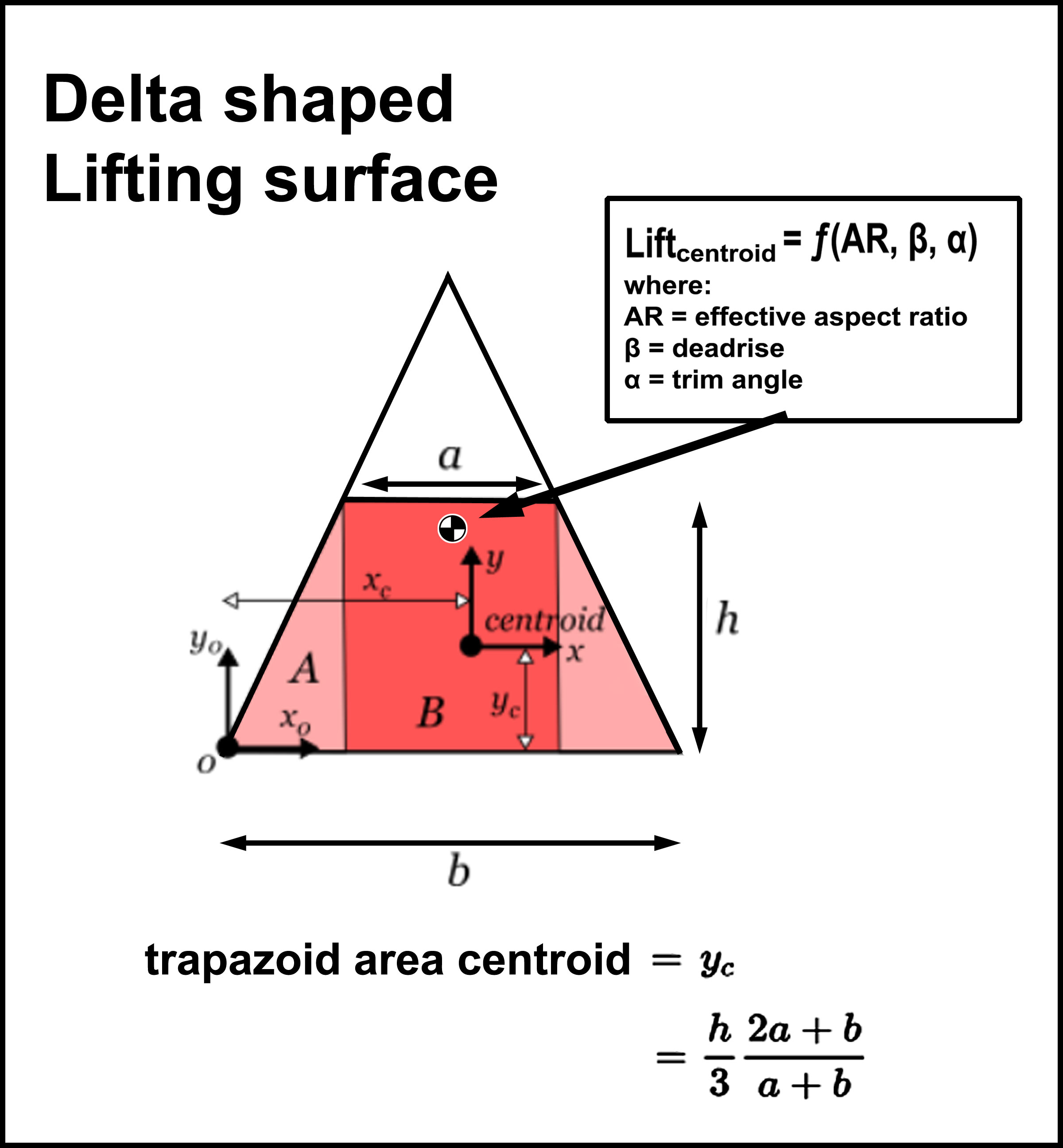

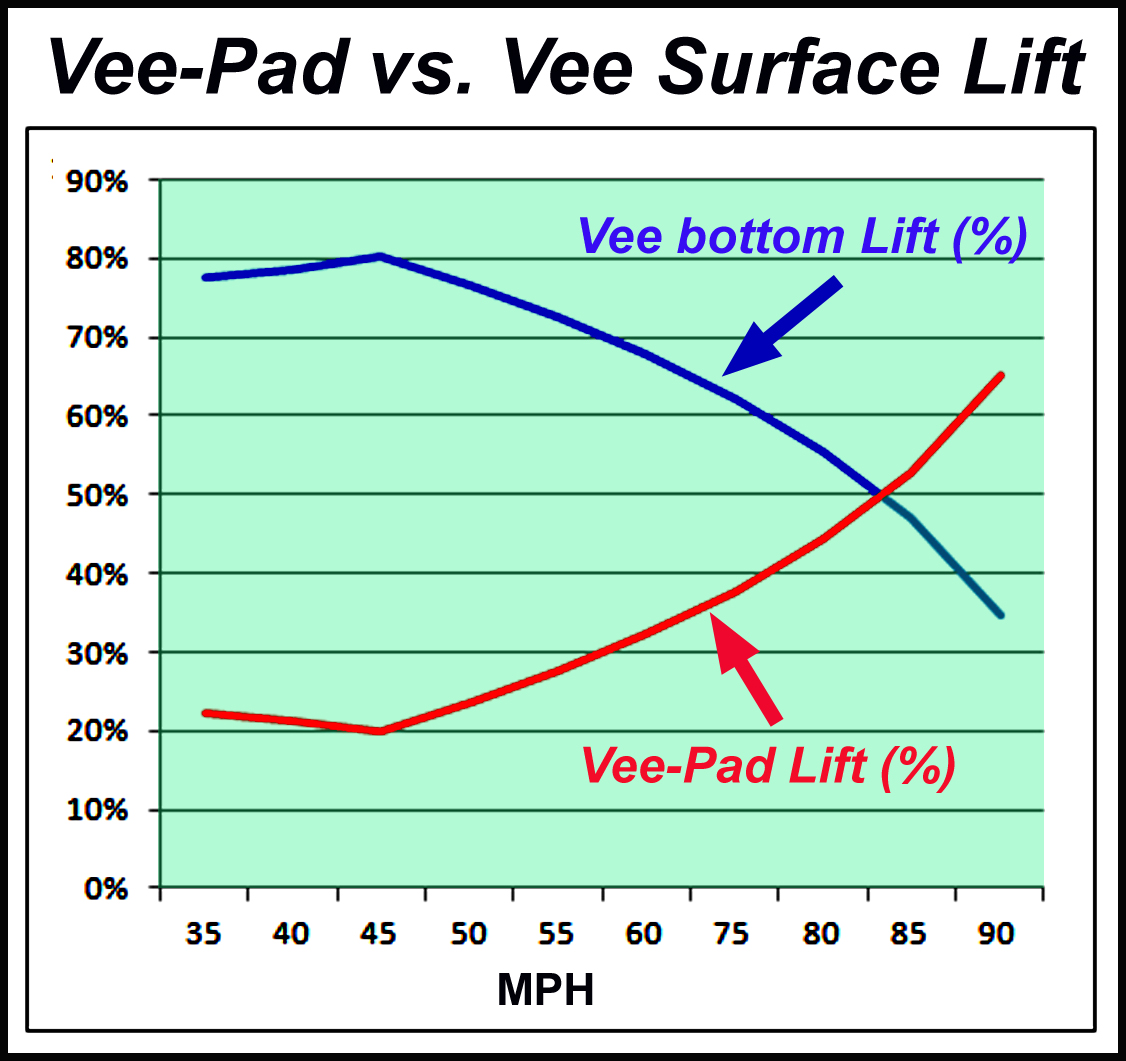

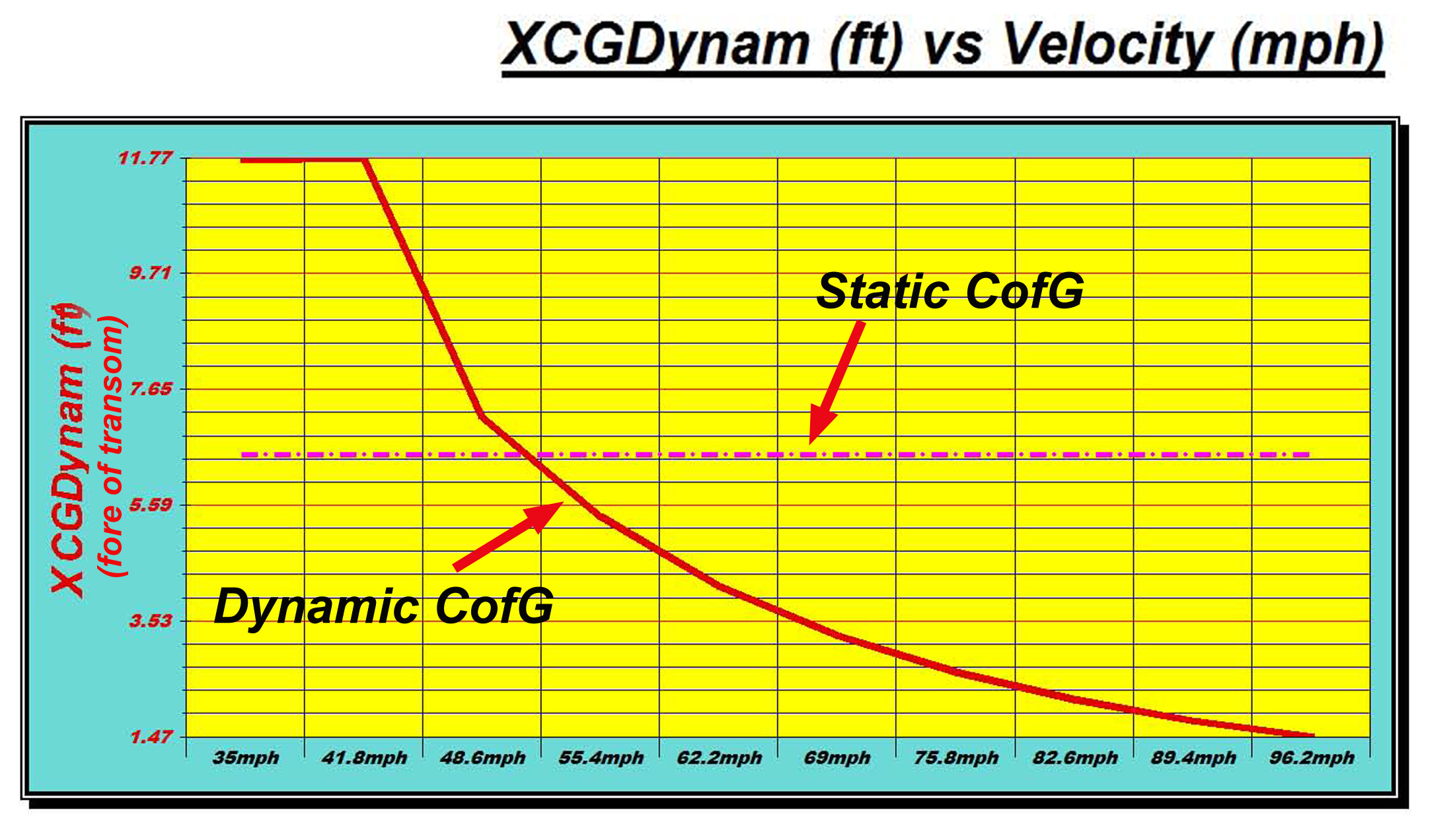

Figure 1- VBDP© graphic output shows the velocity at which your hull configuration experiences instability in Porpoise Regime and susceptibility to porpoising.  Figure 2- Vee-Pad configuration can be analyzed to optimize center-pad width, length, deadrise, height.   Figure 3- Typical rectangular pad shape (upper). Alternative 'delta' trianglular shaped pad (lower).  Figure 4- Typical Delta pad analysis must consider complex, constantly changing effective wetted width, wetted length, wetted area, centroid of lift area, and resolved planing Lift force location.  Figure 5- Effective balancing of Vee-Pad Lift can optimize balance of 'Pad Lift' with 'Vee surface Lift', based on hull weight, configuration, power and speed requirements.  Figure 6- The important 'Dynamic CG' location changes dramatically throughout the operating velocity range of the hull; while the 'Static CG' of boat remains in the same location.  Figure 7-VBDP© software employs unique "Vee-Pad design optimization" technique to provide detailed performance prediction results for easy 'balancing' of vee-pad/vee surface load distribution for any vee hull design/setup arrangement. [see video "Vee Pad Modification" with VBDP©] |

Vee-Pad design optimization is a delicate balance, solved by AR's

unique analysis and VBDP© software. How to optimize design of a vee-pad? Copying a design that seems to work well on one boat will not necessarily work on another boat at all. Each vee-pad design must be carefully designed for the vee hull configuration. We have developed an interactive analysis technique that allows designers to see the delicate balance between lift/drag forces of a vee-pad hull. The method can isolate the lift/drag forces for vee-pad, vee (bottom) surfaces, aerodynamic surfaces and lower-unit appendages. The complex interaction of centre vee-pad and other vee surfaces is resolved in AR proven algorithms. The technique gives designers, builders, owners and operators the ability to optimize vee-pad dimensions and setup to fine-tune the lift gained from the "pad" portion and "vee surface" portions of hull design. The VBDP© software employs the unique "Vee-Pad design optimization" technique and provides detailed performance prediction results and graphic performance output that allows for easy 'balancing' of vee-pad/vee surface load distribution for any vee hull design/setup arrangement.

How it Works The pad is a relatively flat planing surface configured to the aftmost section of a vee shaped hull. The pad (or low deadrise center-section) usually extends sufficiently forward, so that the transition from the vee to the flat running surface is gradual, and usually exhibits some deadrise in the forward section of the extension. The pad has several performance advantages: Balancing Act - the high-performance vee-bottom can be a challenge to drive at high speed. Deeper vees (15°–20°deadrise) must be balanced on a thin keel edge, often exhibiting an unsettling lateral instability, as it “rocks” from side to side. The pad provides a wider platform on which the hull will ride - making it easier to balance at higher speeds. High Lift - The flat pad generates much more efficient Lift than the veg'd bottom shape. Hydrodynamic theory dictates that, in general, a steeper angle of vee (e.g. 20° deadrise)creates less Lift than a shallow angle (e.g. 10° deadrise). The extreme case is the completely flat pad that has zero (0° deadrise) that creates very high Lift for it’s small wetted surface area. The result of this “extra Lift” is reduced hydrodynamic Drag and more speed! During acceleration mode, the pad vee hull gets Lift from the vee-hull sections, as well as the flat pad section. It needs this entire lifting surface at lower velocities, to Lift he weight of the hull. As the speed increases more and more, the required Lift is generated more by the flat pad, and less by the vee'd surfaces. The pad takes on more of the Lift, and more of the vee'd surfaces become “unwetted”. Now there is LESS drag, and a resulting speed increase is quite noticeable. Experienced pad-vee drivers will recognize the “pop” that occurs when the hull reaches that special velocity where the hull “breaks” away from the vee'd lifting surfaces and rides on the pad alone. Optimization of Vee-Pad design - Vee-pad design dimensions and configurations have traditionally been established by "trial-and-error" methods or "duplication" of other designs. These methods can be costly, time consuming and can generate disappointing final results since the ultimate design is not necessarily optimized for the subject design hull. The AR© "Vee-Pad design optimization" technique allows us to attain an effective 'balance' of vee-pad/vee surface load distribution for any vee hull design/setup arrangement. This 'balance' of 'Pad Lift' with 'Vee surface Lift', should be optimized for each unique hull design, setup and operating conditions. Optimization of vee-pad dimensions must be based on unique boat weight, hull configuration, power and speed requirements. Vee-pad characteristics can then be established, including: -pad width -pad length -pad shape -pad deadrise -pad height -pad angle -notch All of these characteristics affect the efficiency of the "high lifting pad" and the portion (%) of Total hull Lift that the pad can provide. Considerations of Vee Pad Benefits - a vee pad will not always improve performance of a vee hull. Some vee hull design attributes that should be considered when evaluating the potential benefits of employing a vee-pad in a hull design include: -vee deadrise -hull weight -target speed -engine hp -performance range desired -dynamic stability -potential for vee-pad 'trip-edge' The VBDP software can evaluate the benefit (or not) of a vee pad design feature, show the comparative performance of the vee-pad feature, and help optimize the design and dimensions of a vee-pad incorporated into a vee hull. VBDP shows in data and graphic formats, over 60+ performance measures of your hull, through the full velocity range, including changes of power level, trim angle; and affects on porpoising, dynamic stability, acceleration, top speed; and comparing affects of different design alternatives of any kind. Vee-Pad shape can affect performance and results. A 'Delta' shaped pad (triangle shape aft to fore) can improve ride in rougher waters, will increase lift contribution as speed increases, but will generate less lift at slower speeds. A 'Std'/rectangular shaped pad can generate higher lift contribution and better acceleration at lower speeds, but may have harder ride in rougher waters. A wider pad will generate higher lift at lower velocities. A std/rectangular shaped pad will generate higher lift than a delta shaped pad, and will have lift centered further forward at lower velocities. If a vee pad is designed to carry a significant portion of total load, then at higher velocities a delta pad should have similar lifting characteristics to a std/rectangular shaped pad. Delta pad analysis must consider the complex changes throughout the velocity range, of constantly changing effective wetted width, wetted length, wetted area. Due to the changing shape of the lifting surface with speed, the 'delta' pad aspect ratio, effective wetted width and centroid of lift area are all complex calculations, and also changing with conditons. Dynamic Stability - The 'Static CG' of a hull is the location of balance of the hull and payload deadweights while boat is at rest. But this is a small part of the important balance of a performance hull. (You can't balance your boat on the trailer!) The combined center of ALL the LIFT forces and all the DRAG forces (sponsons, center-pod, vee surfaces, center-pad, aerodynamic surfaces, lower unit, etc.) while a boat is under way, is called the 'Dynamic Center of Forces' or 'Dynamic CG'. The 'Dynamic CG' location changes throughout the operating velocity range and is the most important design measure to consider when 'balancing' a performance boat. Especially at key velocities, dynamic stability is maximized when the Static CG is close to the Dynamic Stability location. The unique balance of vee-pad forces and vee surface forces in a vee-pad hull make the DYNAMIC balance of the hull important in the design process. [see also AR's 'Advanced Dynamic Stability Analysis research brief'] Results - The "Vee-Pad design optimization" analysis approach can complete an effective 'balance' of vee-pad/vee surface load distribution that will maximize performance and improve dynamic stability. |

||

|

Research results now included in performance

analysis by TBDP©/VBDP© [more about AR's research more about AR's publications and technical articles/papers] |

|||