|

Advanced aerodynamic

analysis technique gives highly accurate lift and drag contributions

to tunnel boat performance predictions & optimization.

Aerodynamic research

has been advanced by AeroMarine Research®, extending traditional

aerodynamic algorithms to account for the complexities of 'ground

proximity', 'end-limited pressure' conditions (tunnel sides), non-symetrical

upper/lower aerofoil surfaces. AR® has developed unique algorithms

to establish highly accurate aerodynamc lift, drag and dynamic stability

results that are specific to tunnel hull, power catamaran, vee hull

and vee-pad hulls. TBDP is the only software that includes

Aerodynamic 'Ground Effects'

analysis.

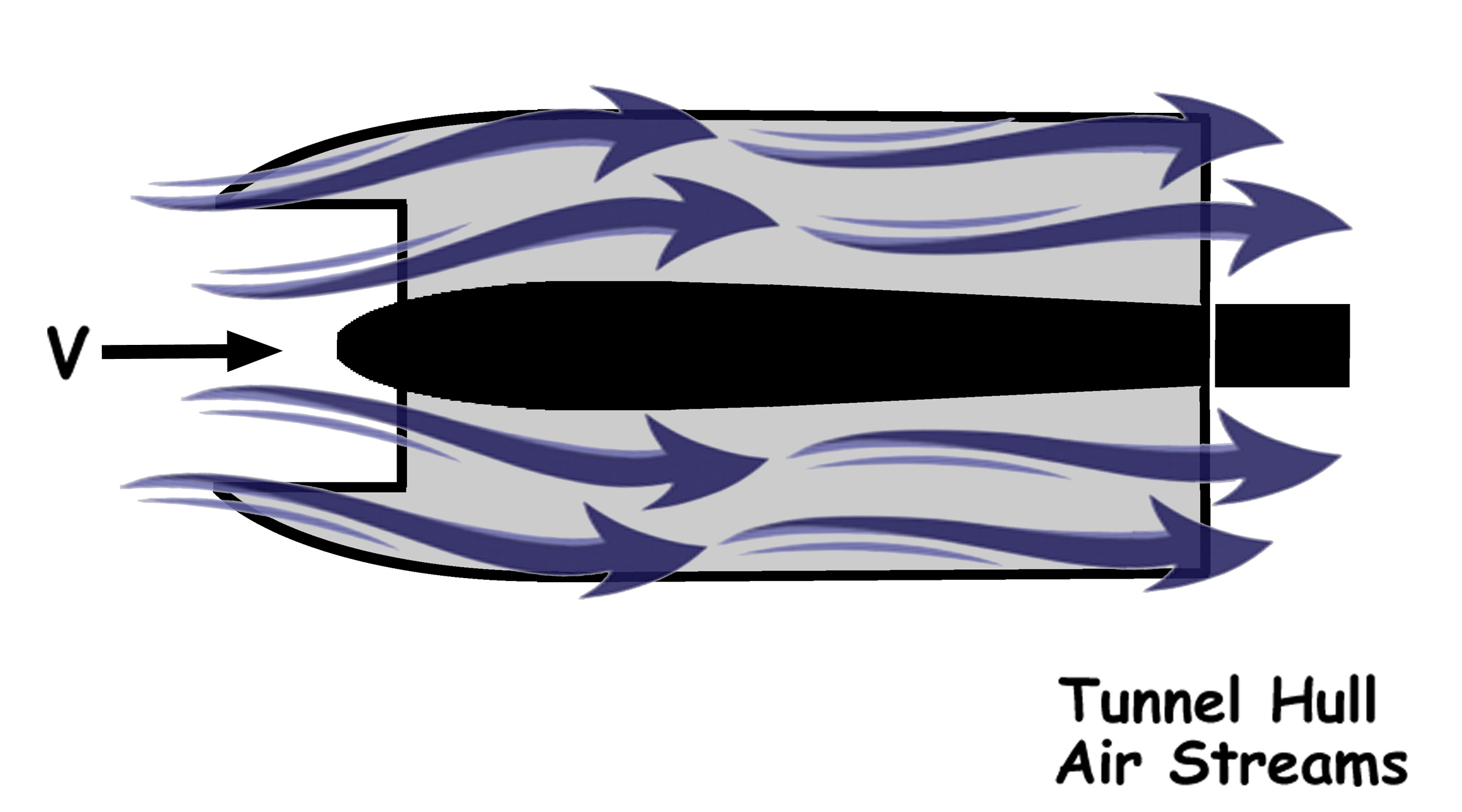

AR conducted unique aerodynamic research that included

wind tunnel assessments, ground effect experiments, and

complex hydrodynamic research, all of which greatly advanced the

understanding of the intricacies of tunnel hull behavior.

Ground-effect tests were conducted in a high-speed, sub-sonic,

wind tunnel using an image-wing (reflection) method. [The

image-wing technique uses an identical model mounted inverted

with respect to the test model in flow stream, and correlates

well with results of a body moving over a surface.]

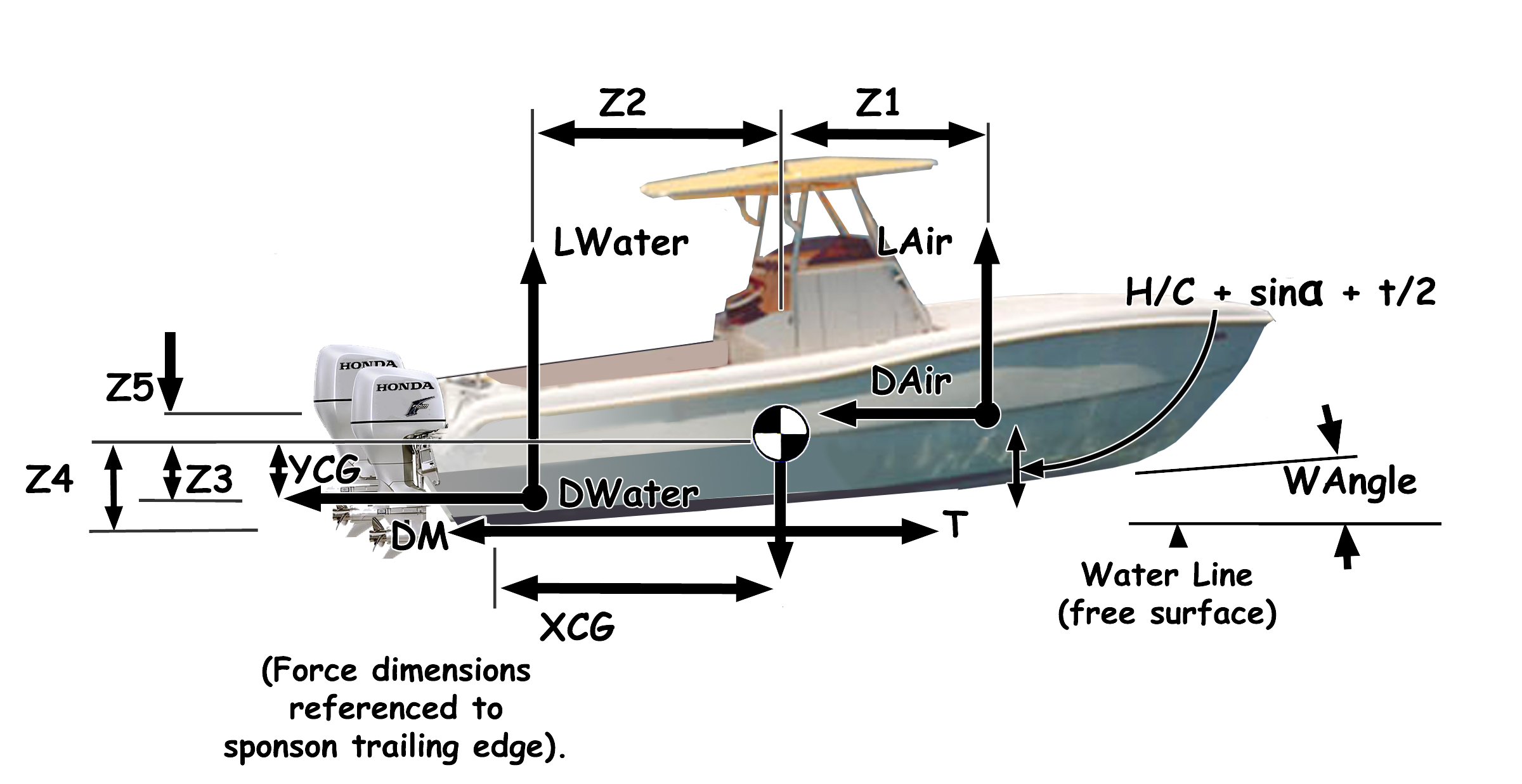

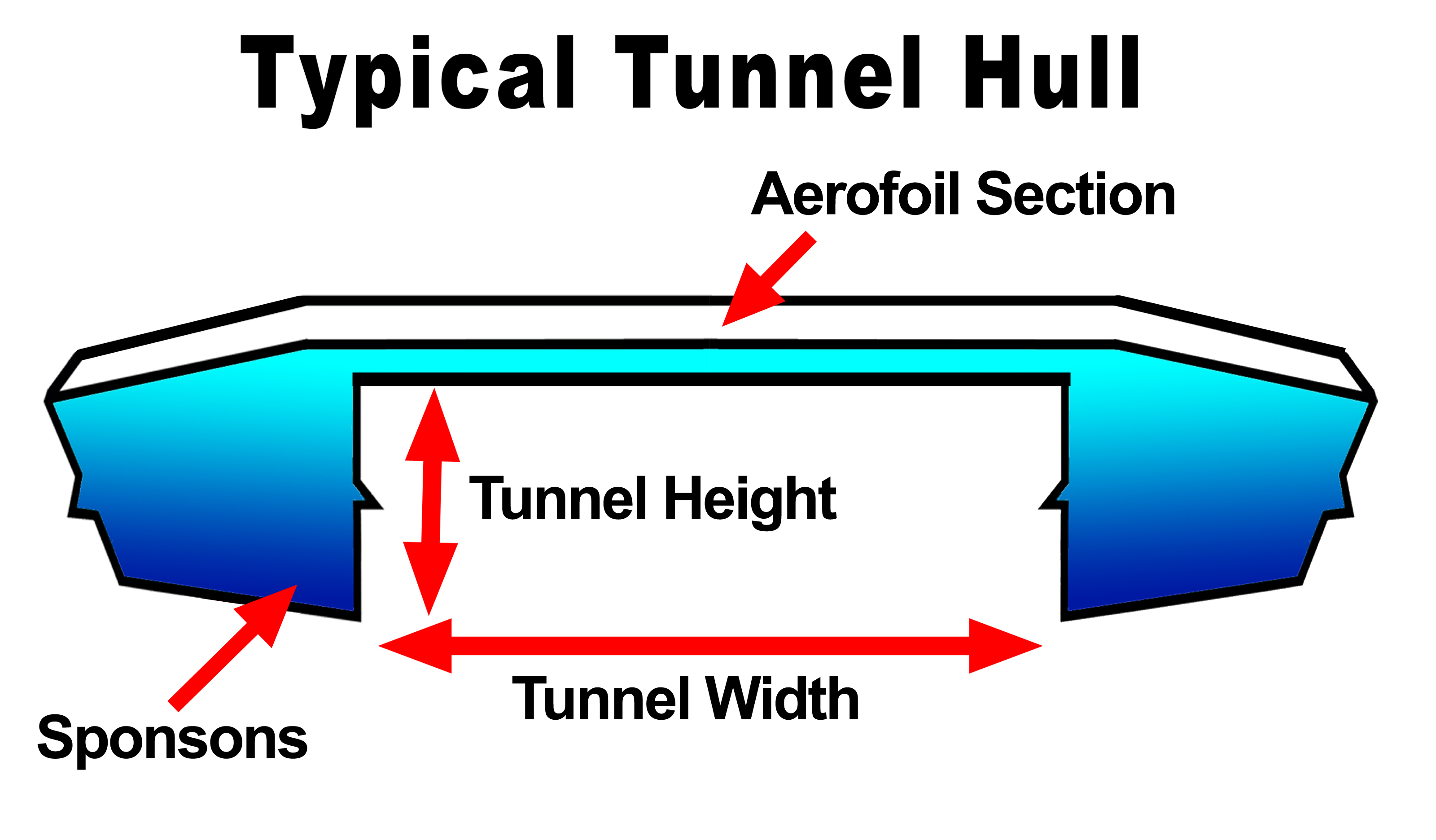

Tunnel boats demonstrate exceptional

performance because they have a 'wing' or aerofoil built-in

to their design. The tunnel “roof” and the upper

deck surface form the lower and upper surfaces of the aerofoil,

respectively. When properly designed, it is this aerofoil,

and the aerodynamic lift it generates using

aerodynamic 'Ground Effects', that gives the tunnel boat

its great performance. A performance tunnel boat must count on the

sponsons for some of the lift for the hull, just as a deep-vee boat

must depend on its narrow running surface to support its weight.

The tunnel hull (and many vee hulls) has the additional advantage

of being able to further reduce the water drag by supplying lift

from its aerodynamic surfaces.

'Ground Effect'

- A properly designed tunnel hull can be considered as a wing in

'ground effect',

(even though it's water that it is 'flying' over). Several

design characteristics affect the influence of aerodynamic

'ground effect' on tunnel hull performance behavior, such as

wing height, aspect ratio, aerofoil thickness, end containment ('winglets'),

aerofoil shape, trim angle (AofA), etc.

For example, 'Wing Height', or 'height of tunnel roof aerofoil

above the water surface'. In most cases, as the tunnel roof runs

closer to the water surface the lift generated increases. This

is called 'ground effect'. An aerofoil or 'wing' in ground

effect has very special characteristics, and the phenomenon is a

study all in itself. [See more on the 'Wings in Ground Effect',

in "Secrets

of Tunnel Boat Design" book]

We have established that a tunnel boat's aerofoil operating close to the

'ground' or water surface causes a tremendously enhanced

Lift/Drag relationship. The much higher pressures generated in

close proximity to the water surface cause an even larger

difference in pressures between the top surface and bottom

surface of the wing, resulting in higher lift forces, and

actually lower aerodynamic drags.

Key is the integration of aerodynamic forces with the other

hydrodynamic lift and drag forces operating simultaneously under

all conditions.

TBDP©/VBDP© is the only powerboat design software that

accounts for the complex influences of 'ground effect' on tunnel

hull performance.

Aerodynamic Lift - A properly

designed tunnel hull can be considered as a wing in 'ground effect',

(even though it's water that it is 'flying' over). Every pound

of lift that can be generated by this 'wing', is one less pound

of lift that doesn't have to be supplied by the hydrodynamic lifting

surfaces ‑ which bring unwanted water drag.

Many inter-dependance factors are involved

in creating the lift generated by the tunnel and the deck surfaces,

or this 'wing'. This consideration is the same for all sizes,

configurations, weights, speeds, power of tunnel boats and catamarans.

The main contributors can be summarized as:

a) Airspeed

b)

Angle-of-attack

c) Effective aerodynamic Lifting Area

d)

Aspect Ratio of Tunnel (chord/width)

e) Height above the water

surface

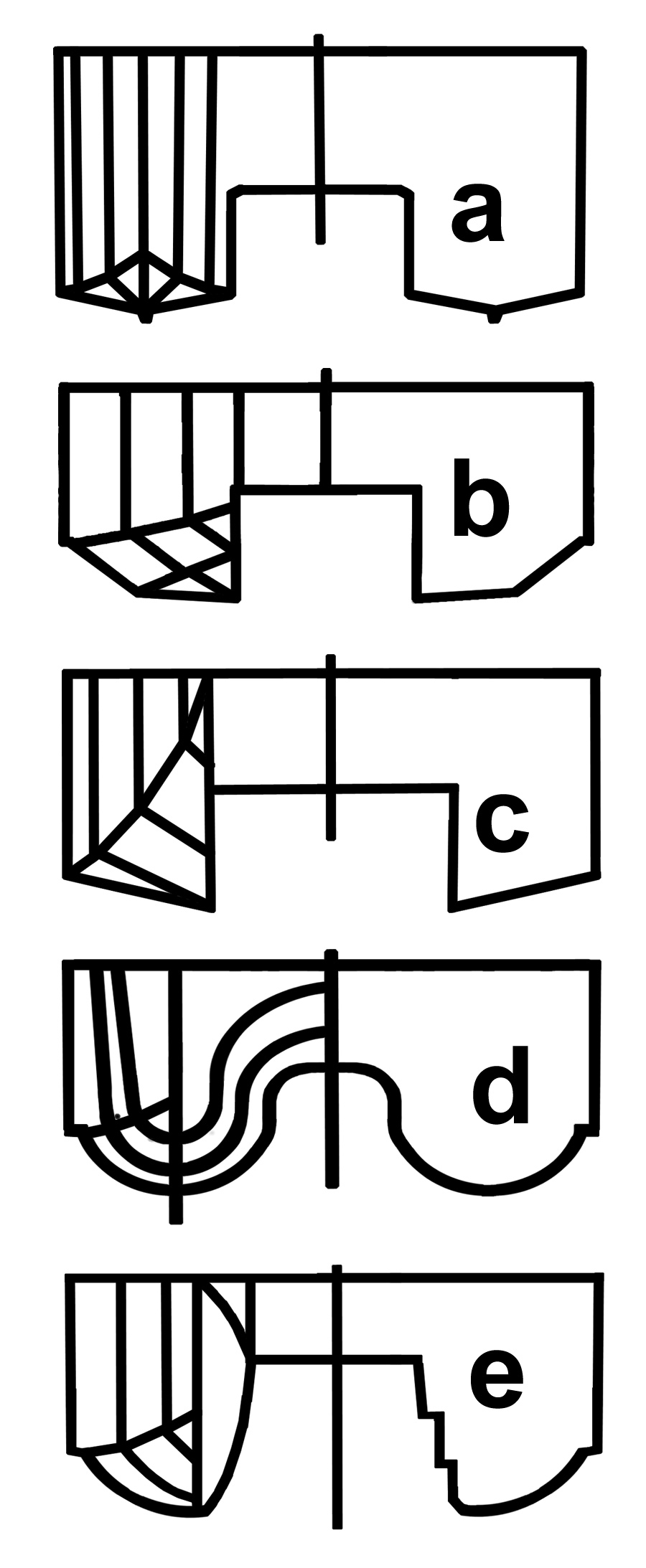

f) Aerofoil shape of tunnel cross-section

g) Aerofoil

thickness

h) Surface condition (roughness) of exposed areas

[TBDP©/VBDP© performs

for all hull types, all sizes, all powers, all speeds.]

Complex fluid flow modeling specifically

for tunnel and vee hulls allows accurate computer modeling of these

complex designs that fly in air and on water. Aerodynamic

'Ground Effects' are analyzed and included in performance

analysis of tunnel hull and vee hull configurations.

Important Considerations -

Forces acting on a tunnel hull must include

the influence complex planing surfaces (steps, lifting strakes,

centre-pad/pod surfaces, etc.), and of non-planing forces (aerodynamic

contributions from low aspect ratio ground effect hull forms, etc.).

While the normalized derivation for lift from hydrodynamic surfaces

is...

LA

= ˝ • ρA

• V2

• SA •

CLA

where:

LA

= hydrodynamic (water) lift

ρA

= density of water

V = velocity

SA

= effective wetted surface area

CLA=

lift coefficient

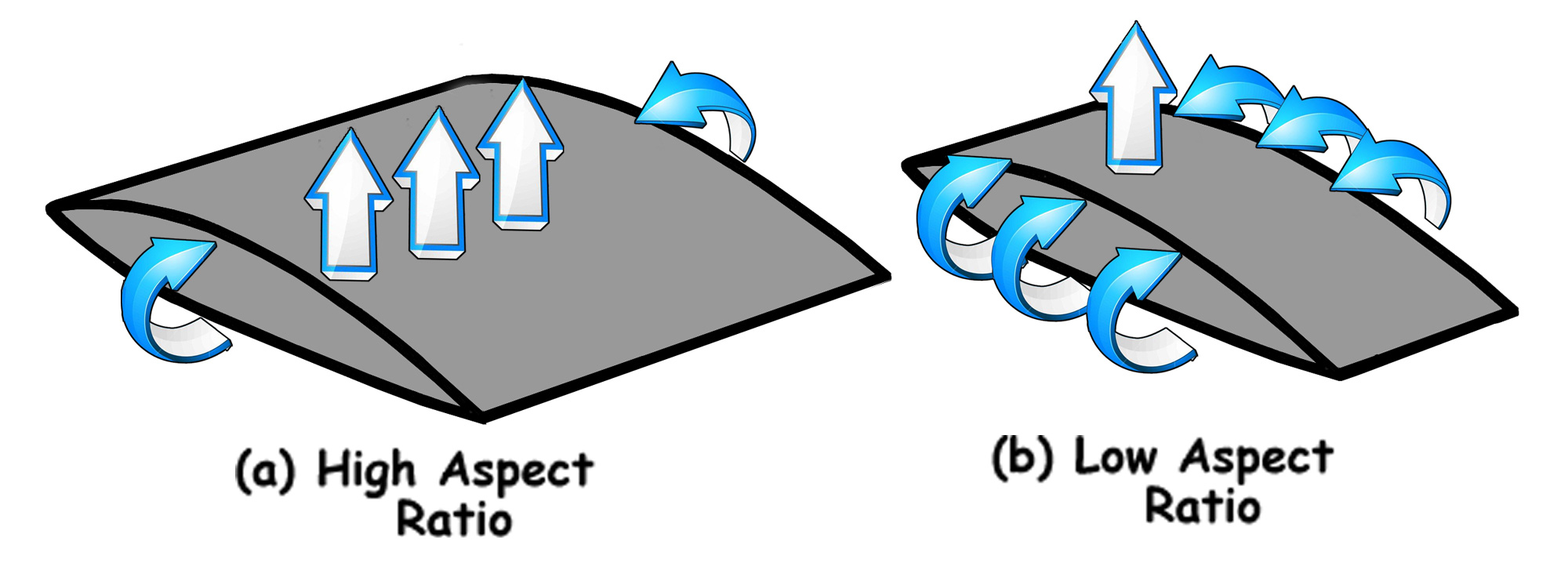

An advantage of tunnel hull designs is the entrapment feature

of the lower aerofoil surface or 'tunnel' section, through the 'end-plate'

provided by outboard sponsons. Normally higher aspect ratio

wings tend to increase net lift because mainly, of the reduced opportunity

for the 'escape' of high pressure air around the 'wing tips' to

the upper surface. This 'escape' of air causes what is called

a 'wing-tip vortex', reducing lift and increasing drag. The

outboard sponsons on each side of the tunnel section, act as 'wing

end plates' that restrict this 'escape' of airflow, enhancing aerodynamic

performance.

The establishment of effective surfaces and related CLA

is necessarily complex. The above influencing variables are changing

constantly with hull velocity, making the accurate accomodation

very complex. What's more, each of these variables are interdependant

(on each other), so the accurate analysis of CLA, total Lift

and total Drag is tricky.

Aerodynamic Drag

-

The total drag created by the hull must be overcome by the available

thrust - namely the engine/propeller. The drag of a tunnel

hull is made up of both aerodynamic or 'air' drag (drag from the

tunnel/deck surfaces, appendage air drags such as driver, cockpit

area, motor, etc.) and hydrodynamic or 'water drag' (from the planing

sponsons and motor appendages under water).

As with tunnel lift, the air drag increases primarily with the

square of the velocity and as angle-of-attack increases.

This air drag originates in three (3) forms:

a) Skin Friction

b) Induced Drag

c) Profile Drag

Also, the aerodynamic lift/drag is strongly influenced by the

complex interdependence of hydrodynamic Lift/Drag and other appendage

drags (cockpit

aero drag,

cavity drag, engine

lower unit

drag, etc.) - all affecting CLA, SA

and LA of aerodynamic

lifting surfaces.

'Aerodynamic Roughness'

also affects aerodynamic Lift/Drag coefficients based on

relative aerodynamic smoothness of deck, tunnel, cockpit

surfaces, and should be accomodated.

[The analysis methods in 'Secrets

of Tunnel Boat Design - Second Edition' [ISBN#

978-0-9780586-1-6, pub: 2024] and AeroMarine

Research TBDP©/VBDP©

software demonstrate the development of proven algorithms that solve

all of these challenges accurately.]

Aerodynamic Center of Pressure - The

Lift forces generated by a tunnel hull 'wing' act through it's

'Center of Pressure', (CofP). This CofP location affects

the total balance of forces of the boat, and hence,

dynamic stablity. The aerofoil shape affects the

location of the CofP. The CofP location also changes with

Veloctiy and 'Trim Angle'. As this CofP location changes

during acceleration or deceleration, so does the dynamic

stability, so aerofoil selection is important to optimize the

balance of more/less lift with change in stability.

Sponson Sides Enhance Aero

Lift - A wing derives its lift by the

difference between a high pressure on the underside of the wing

compared to a lower pressure on the topside. This difference in

pressure results in an upward force. Some airplanes attain

improved lift by adding ‘wing-tip-ends’ or ‘winglets’ that

prevent airflow from escaping around the end of the wing,

causing ‘wing tip vortices’ and reduced lift/drag efficiency.

An advantage of tunnel hull designs is the entrapment feature

of the lower aerofoil surface or 'tunnel' section, through the

‘built-in’ wing-tip ends formed by the sponsons on either side

of the tunnel section. This significantly increases the

efficiency of tunnel lift with more lift and less drag

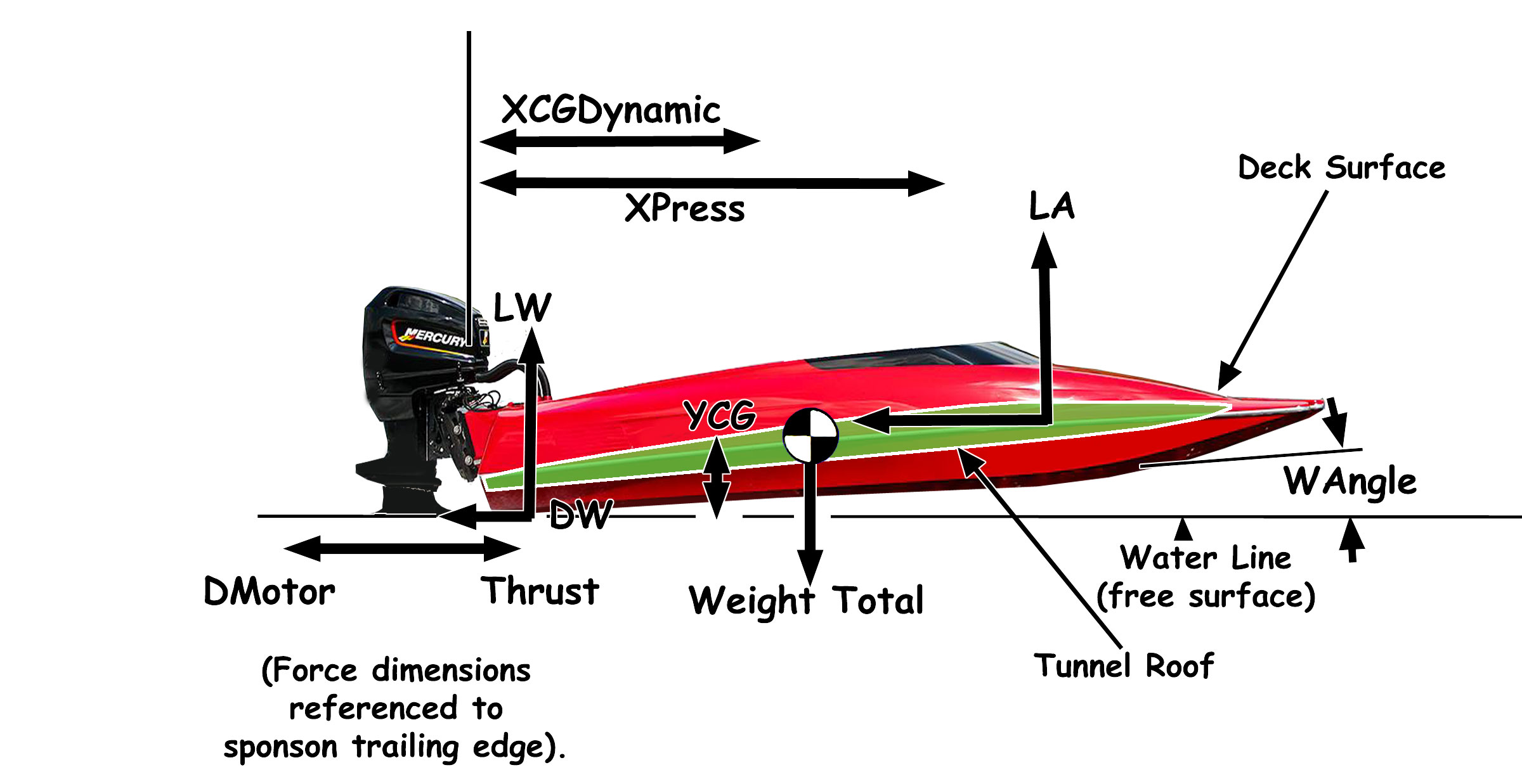

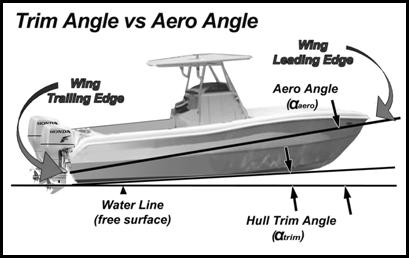

Trim Angle vs Aero Angle

-

Some tunnel boats are designed so that the 'wing' portion of the

hull will operate at an incrementally higher angle of attack

(aero angle, αaero) compared to the hull 'trim angle' (αtrim).

This feature is quite common in many tunnel hulls and power

catamaran designs, particularly weight and power sensitive

setups. The αaero feature is easily identifiable by observing

the tunnel height at the bow of the boat at a higher dimension

than the height of tunnel at the transom. The higher angle of

the 'wing' hull section allows for better seaworthy behavior in

heavier waves and also achieves more aerodynamic lift. So, when

the hull trim angle (αtrim) is say, 3°, the 'wing' experiences a

local angle of attack (αaero) of 5°. This feature generates

higher aerodynamic Lift (and also higher Drag), and is often

more beneficial to overall performance.

Dynamic Stability -

When one of the many influencing forces change, the

aerodynamic lift/drags and WAngle (trim angle) and

dynamic stability are systematically affected. The analysis

to balance these inter-dependent forces throughout velocity range

is complex, and is key to accurate performance prediction.

The AeroMarine Research TBDP©/VBDP©

software doesn't use any 'C' constants, 'shape coefficients' or

'speed factors' to simulate different hull types, shapes or velocity/size

ranges. - it analyzes all design and dimensional aspects of each

hull from first engineering principles, proven by research and full-scale

testing. [This is a unique feature of TBDP©/VBDP©, as most

all other performance analysis software products rely on choosing

'fudge-factors' to adjust results to expected hull types! TBDP©/VBDP©

software gets the right answer based on pure hull design. No

fudge factors are required. ]

TBDP©/VBDP© software uses Finite

Element analysis techniques to accurately calculate the many affecting

hydrodynamic factors that are constantly changing and highly influence

each other. The power of these techniques and the software allows

for comprehensive analysis, employing engineering techniques that

include the critical inter-dependence of aerodynamic, hydrodynamic

and stability calculation methods that are key to proper Tunnel

hull design and accurate performance prediction.

Russell's development of Advanced

aerodynamic techniques were proven

through

wind tunnel testing, water channel testing and full scale

hull verification testing.

How it Works - Any performance hull will perform better when taking best

advantage of 'aerodynamic' lift. Any amount of 'aero lift' will

improve a boats performance − even a seemingly small amount.

If we compare 2 boats each weighing 1500 pounds, that means

1500 pounds of total lift must be generated by the hull. At

say, 50 mph, the first boat with no aerodynamic lift capability

requires all of its lift to be supplied from an area of wetted

planing surface. If the second boat can contribute (even only)

100 pounds of aerodynamic lift (that's only 6% of the total lift

required) then only 1400 pounds of water-lift remain to be

generated, which requires less wetted surface area and a

corresponding reduction in hydrodynamic (water) drag.

Less drag means more efficiency and better performance. In

this case, the reduced wetted surface of the second boat results

in a 9% reduction in water drag − just like gaining 10 to 15 hp

and much improved fuel economy, or an additional 5 mph!

The performance

effects of all design and setup features that influence

aerodynamic lifts, drags and dynamic stabiltiy for all Vee hull, Vee-pad hull,

tunnel hull and modified-tunnel hull types of powerboat applications

is developed by Russell. The results are highly accurate representations

of aerodynamic forces and inter-dependence with hydrodynamic

forces associated with all powerboat configurations,

using Russell's analysis techniques in the "Tunnel Boat Design

Program" and "Vee Boat Design Program" software.

Russell

applies these advancements in newest versions of AR's

TBDP©/VBDP© performance analysis software.

|