|

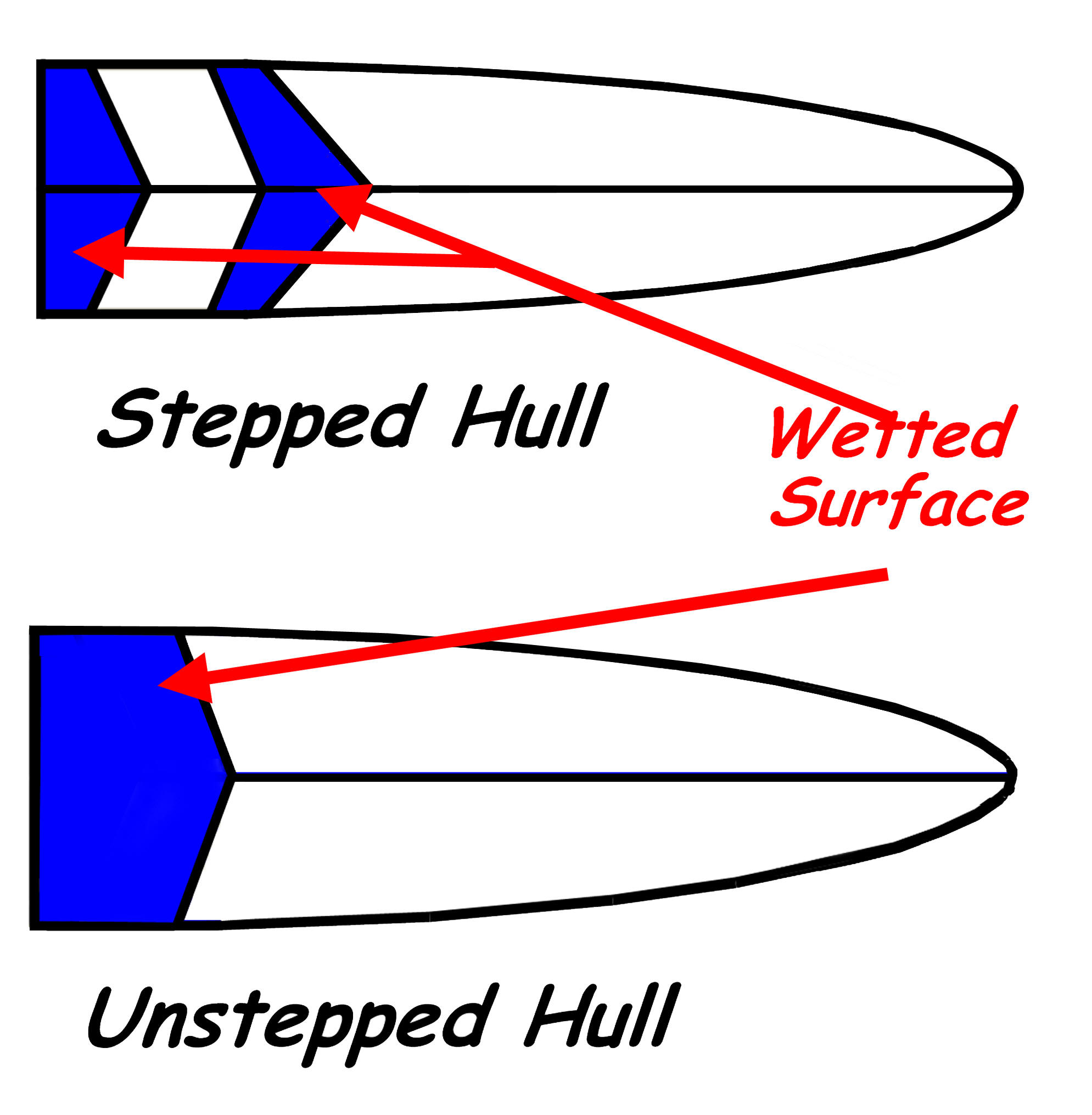

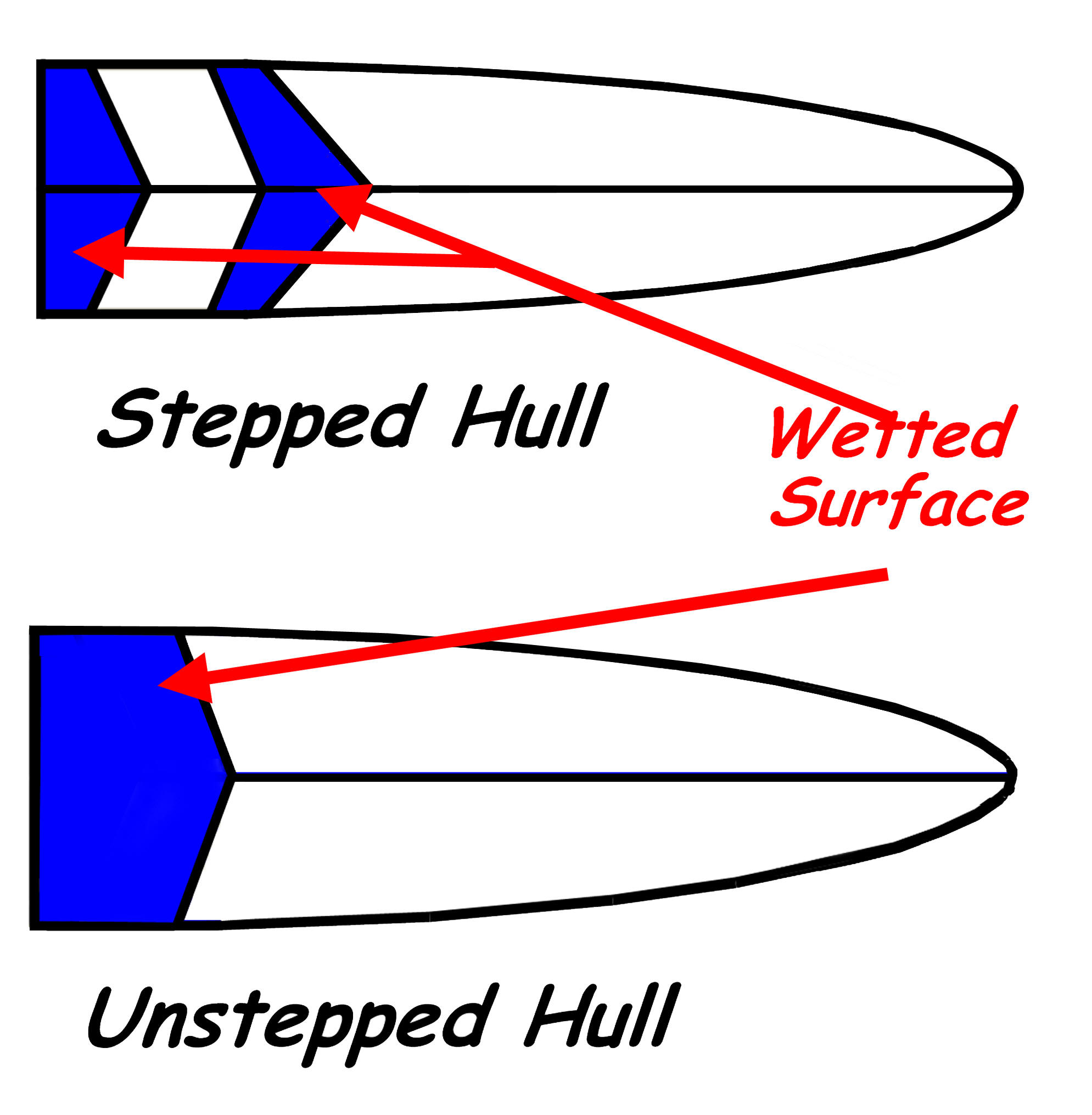

Stepped hull geometry is complex, and

generates better Lift/Drag ratios due to higher Aspect ratio for similar

wetted surfaces.

For Vee hulls (left) and Tunnel hulls (right),

Steps can generate required wetted surface with improved

Lift and Drag characteristics.

Stepped hulls operate with a larger effective

angle of attack due to the inherent step angle 'built-in' to the

planing surfaces.

Wetted surfaces of each stepped area have a

controlled location of forces, and usually enhanced Lift efficiency due

to local 'angle of attack' and higher local aspect ratio.

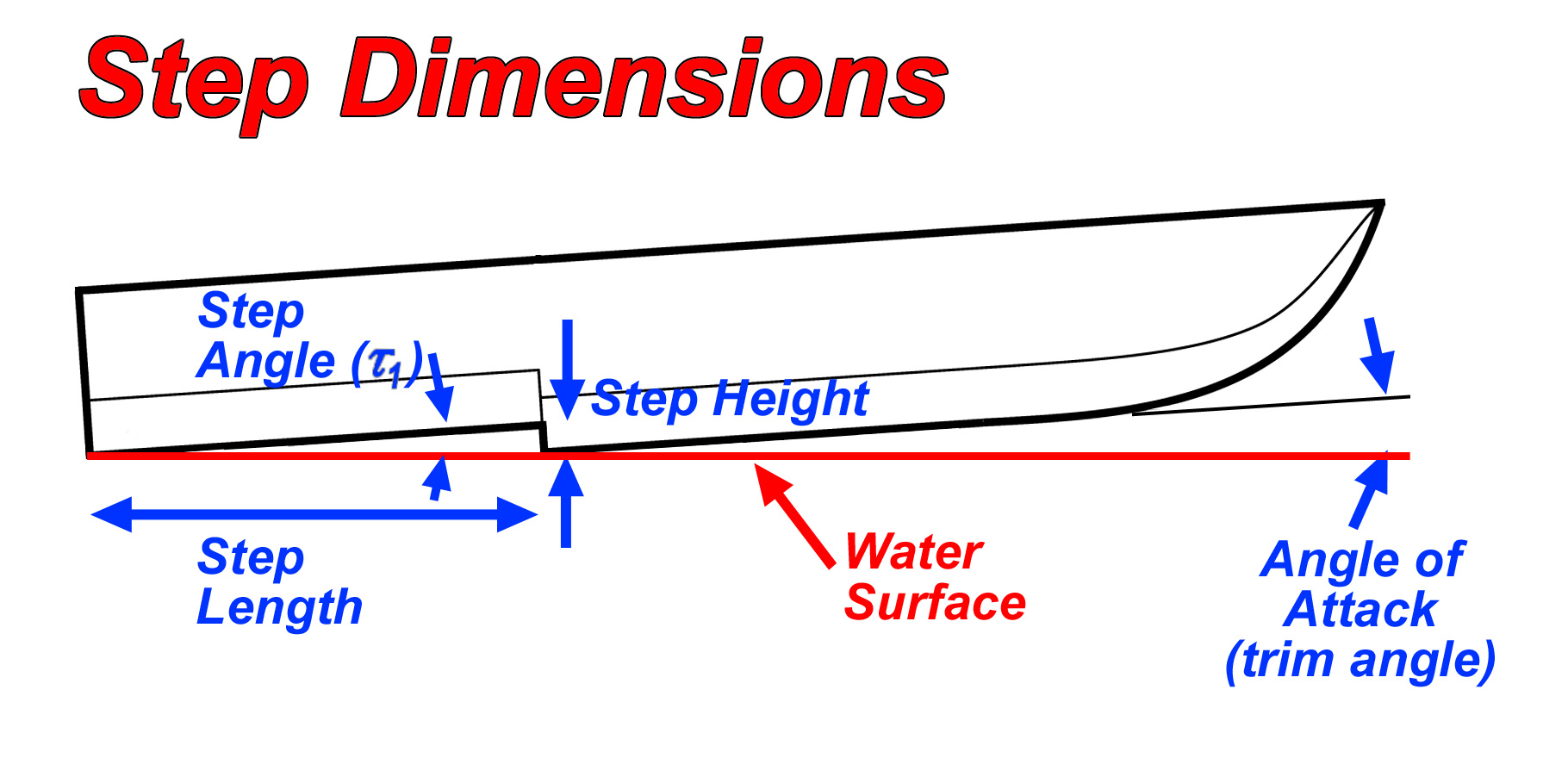

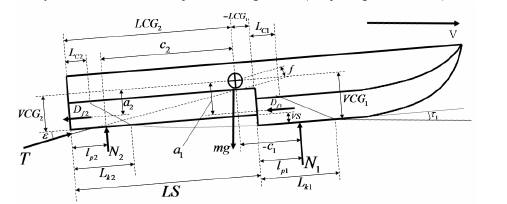

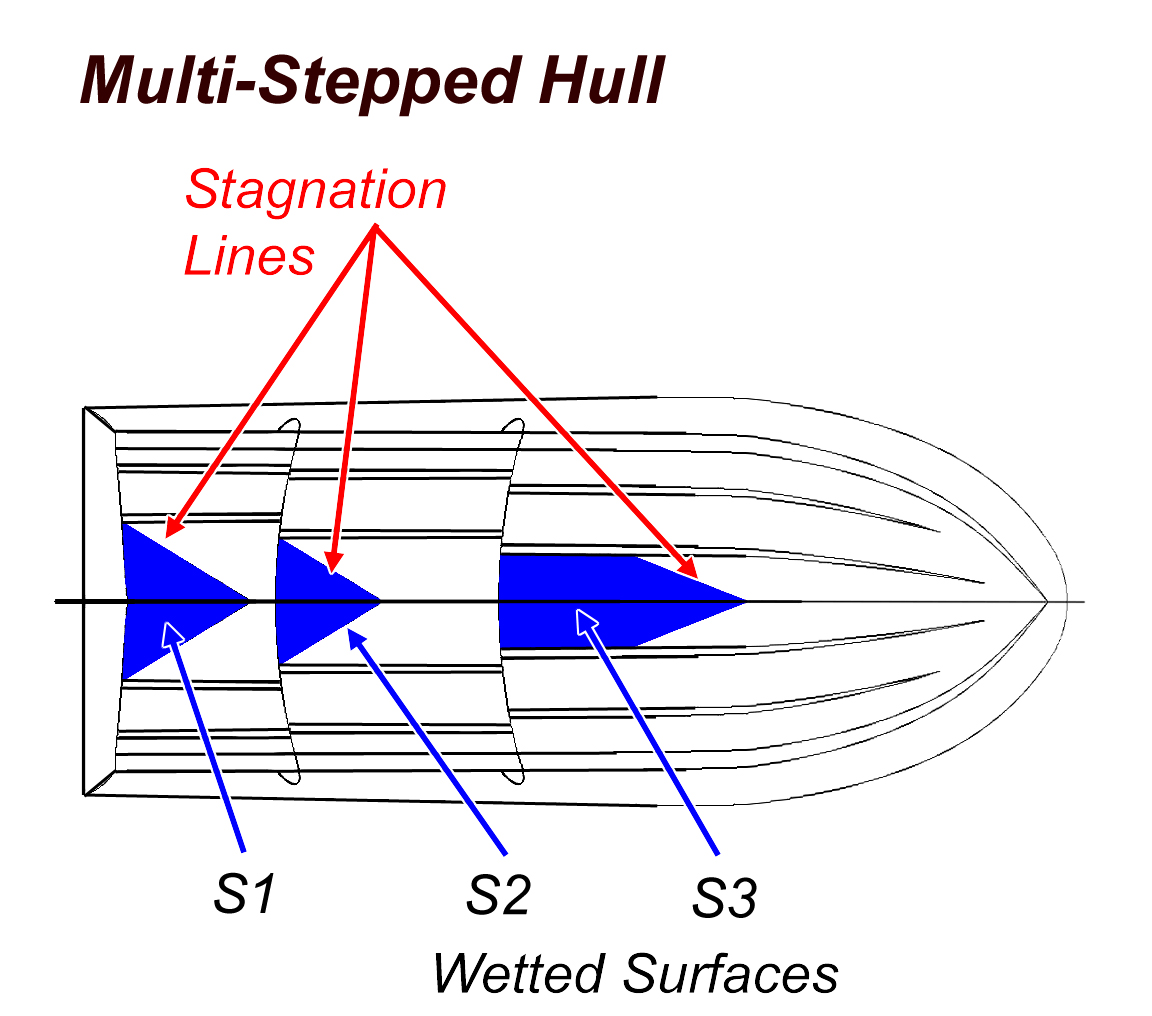

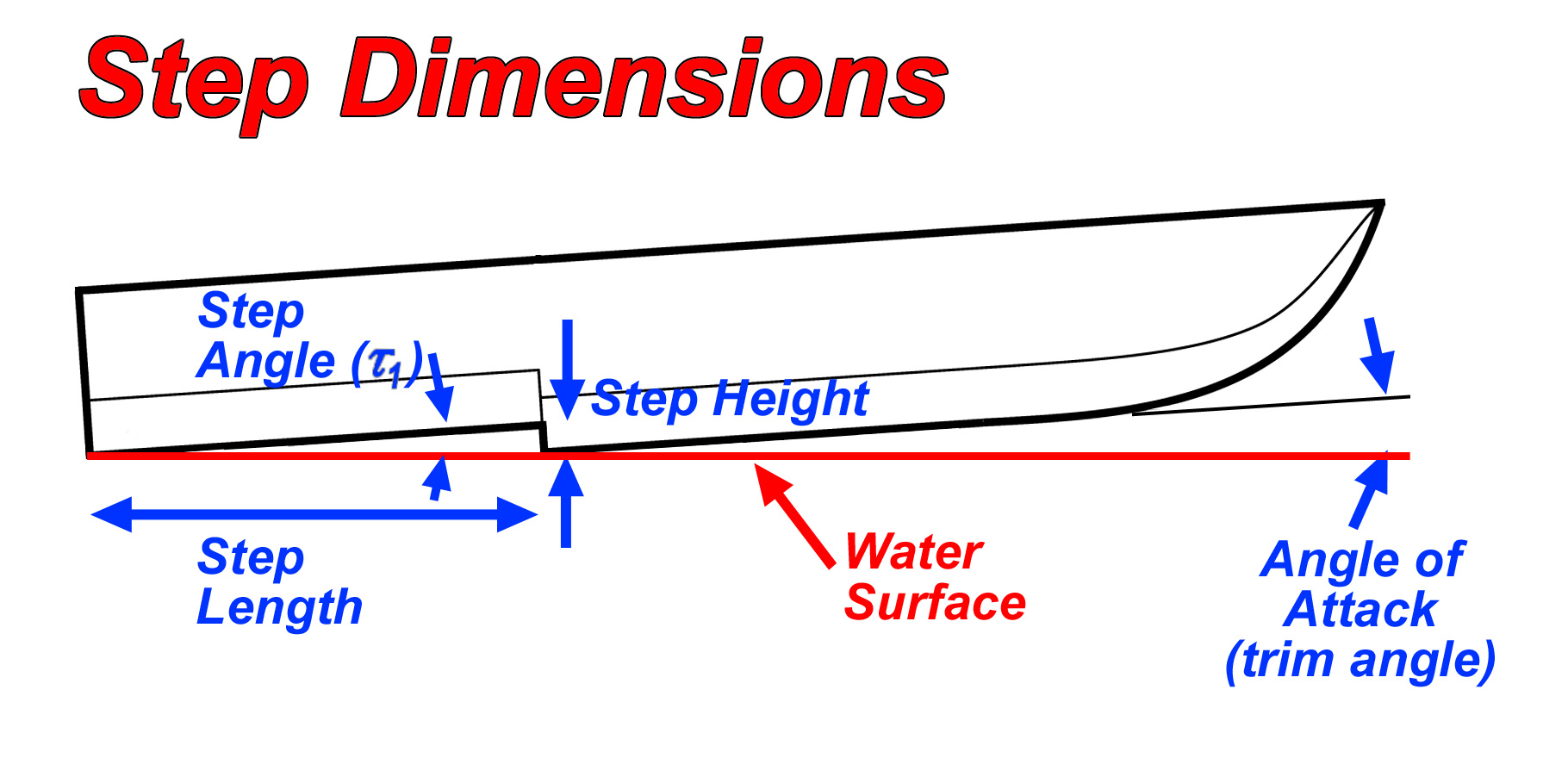

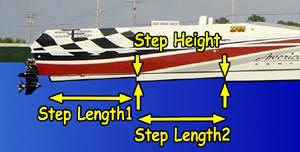

Dimensions of Step configuration are

referenced relative to the 'Water surface'.

Multiple Steps can improve performance through greater velocity range.

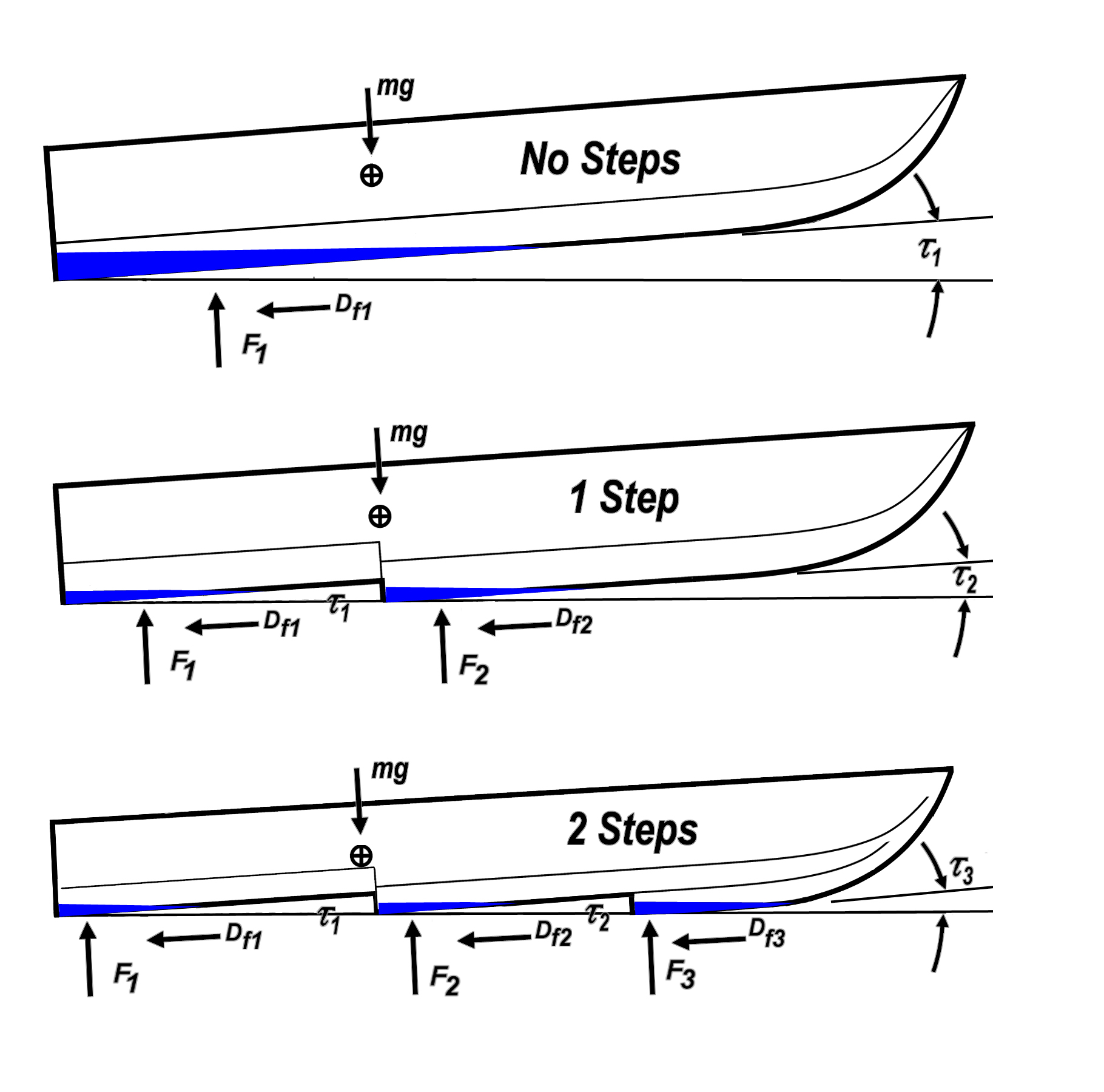

Stepped Vee hull

model.

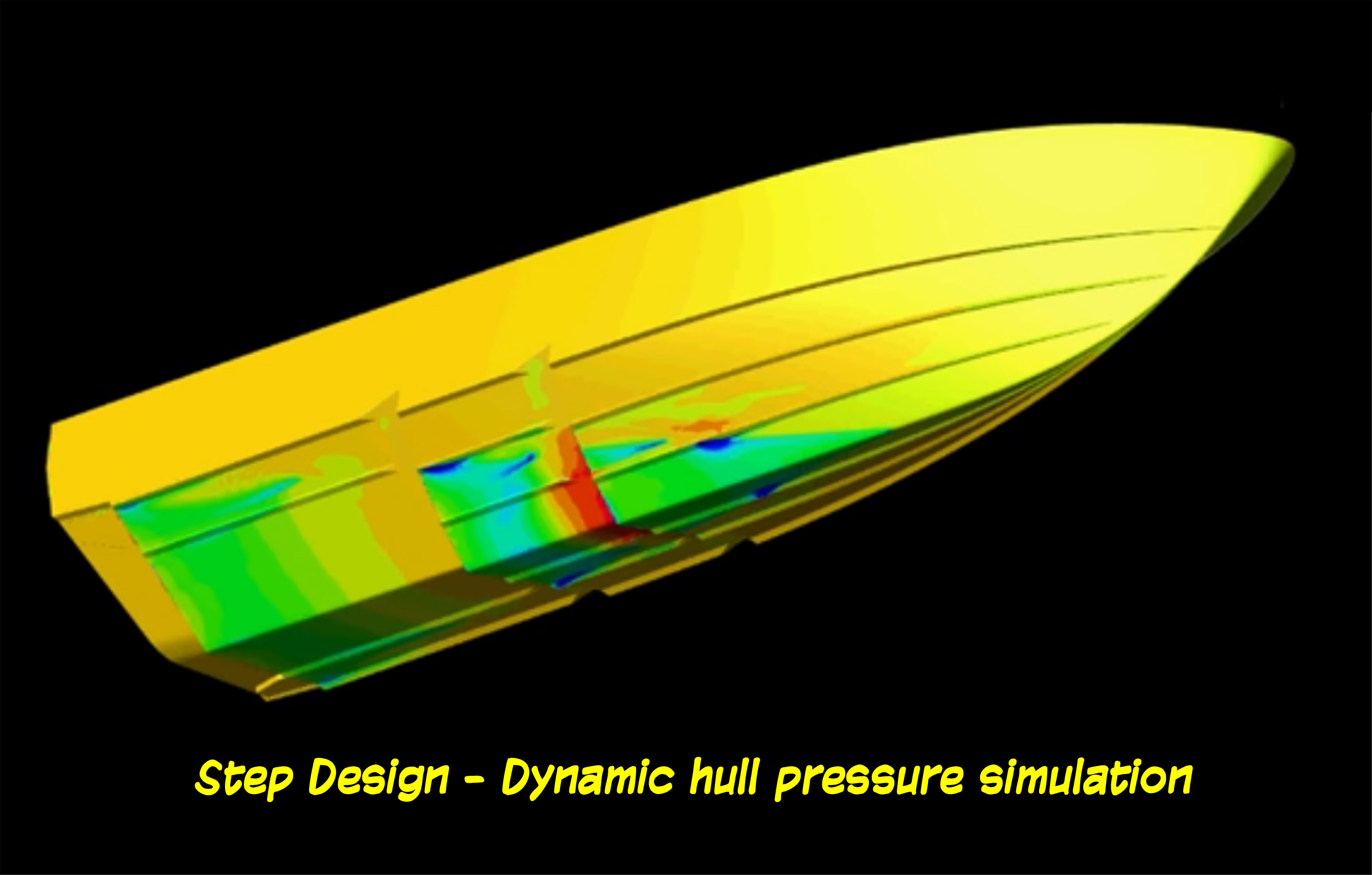

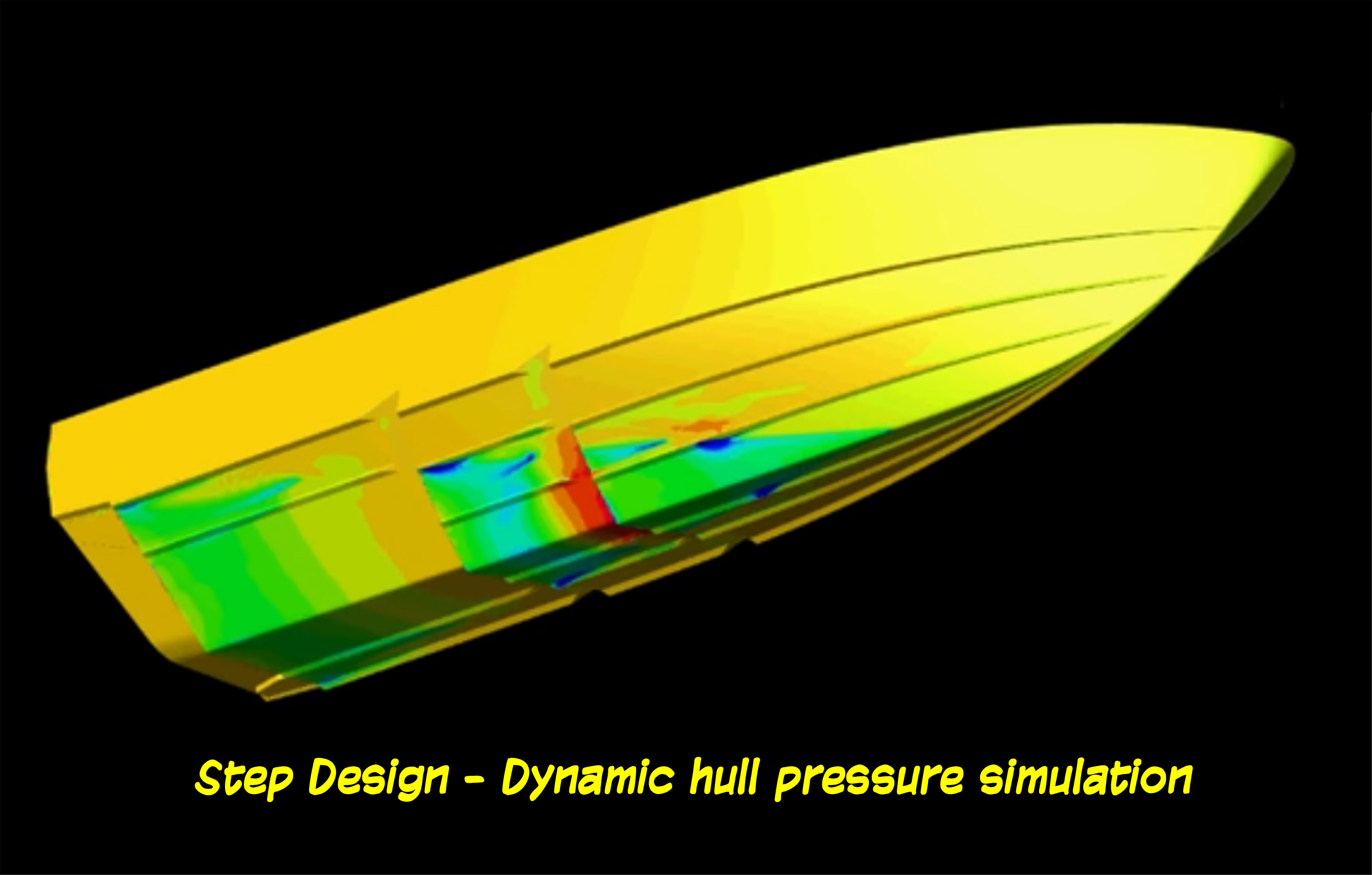

Simulation - Stepped vee

hull pressure distribution

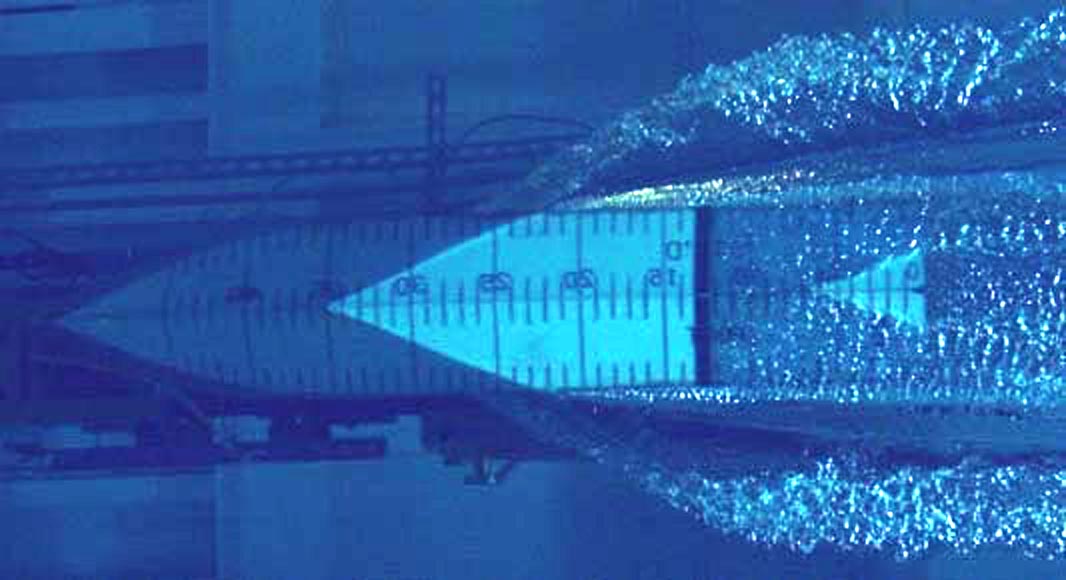

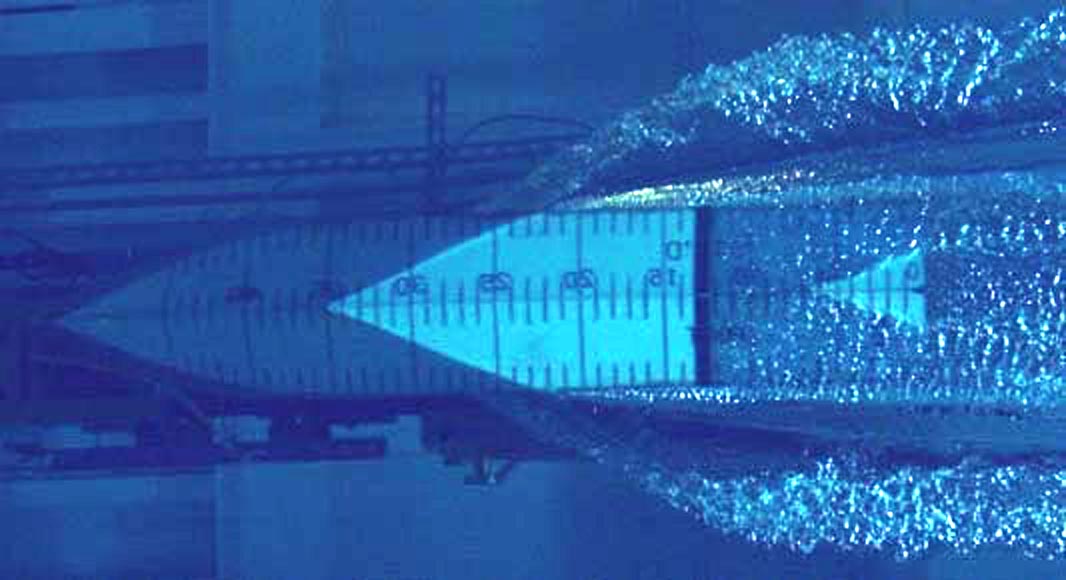

Typical stepped hull wetted surface,

water channel proof testing.

'Steps Analysis' report [excerpt

TBDP/VBDP performance analysis report, pg 1 of 4pgs]. |

|

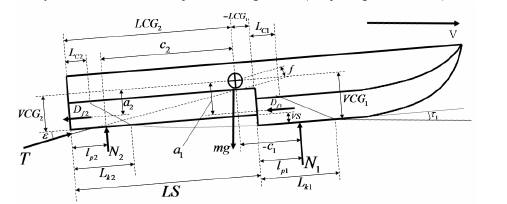

AR® has developed advanced analysis techniques that accurately calculate

the performance effects of single or multiple steps in

tunnel hulls and

vee

hulls.

Complex Analysis and Results

TBDP©/VBDP© software provides a step analysis

through the full operating velocity range, including trim angle, dynamic

stability, changing wetted lengths for each step(s) section, calc'd

velocity when each step becomes 'unwetted', location of lift/pressure forces for

each stepped planing surface, total hydrodynamic lift force map, step

angles, even

effects on porpoising. Comparative/optimizing analysis is simple provided

by graphically comparing results of different design

alternatives.

Making a Step Work

A stepped hull can

be visualized as a flat or deadrise bottom with longitudinal "offsets".

When functioning, the area immediately aft of each step is void of water -

an air or air/water mixture. At low speeds, the entire hull bottom

is in the water, but at higher speeds only a portion of each step is wet,

so theoretically we should get less hull drag.

The stepped hull

creates 2 (or more) planing surfaces that helps maintain a constant (trim)

angle of attack for more efficient lifting. The stepped hull has less

bottom surface in contact with the water creating less drag and allows for more

potential speed.

The 'fore' and 'aft' planing surfaces created by the

'step' have two main

advantages...

1) Steps can maintain a constant and near optimum angle of attack

throughout a wider speed range; and,

2) Steps can reduce the amount

of wetted surface that is not near the leading edge (and would otherwise

produce less efficient lift).

Jim Russell applies these advancements in

newest versions of AR®'s TBDP©/VBDP© performance

analysis software. Your design inputs are pretty simple, but the

analysis is complex and the performance results are outstanding!

Step

Design

The design of an effectively performing step will most

always achieve optimum 'benefits' (more than the 'losses') at only one

velocity. A step design is generally only good for a single (trim) angle

of attack with a single center of gravity (LCofG). This is why it is

complicated to find a step design that can "help" the performance

throughout the entire speed range of a performance boat.

The

planing surfaces of the stepped hulls operate with a larger effective

angle of attack due to the inherent 'Step Angle' that is 'built-in' to the

planing surfaces. Even though the hull 'Trim' angle is often less, the

higher total angle of attack can generate improved CLW (more efficient

Lift). The result is a lesser (total) wetted surface requirement and less

Drag.

Location of LW (planing surfaces hydrodynamic lift) is

normally located further forward in a stepped hull design, as compared to

a non-stepped hull. This can sometimes have a desirable effect on

XCFDynamic (Dynamic Center of Forces).

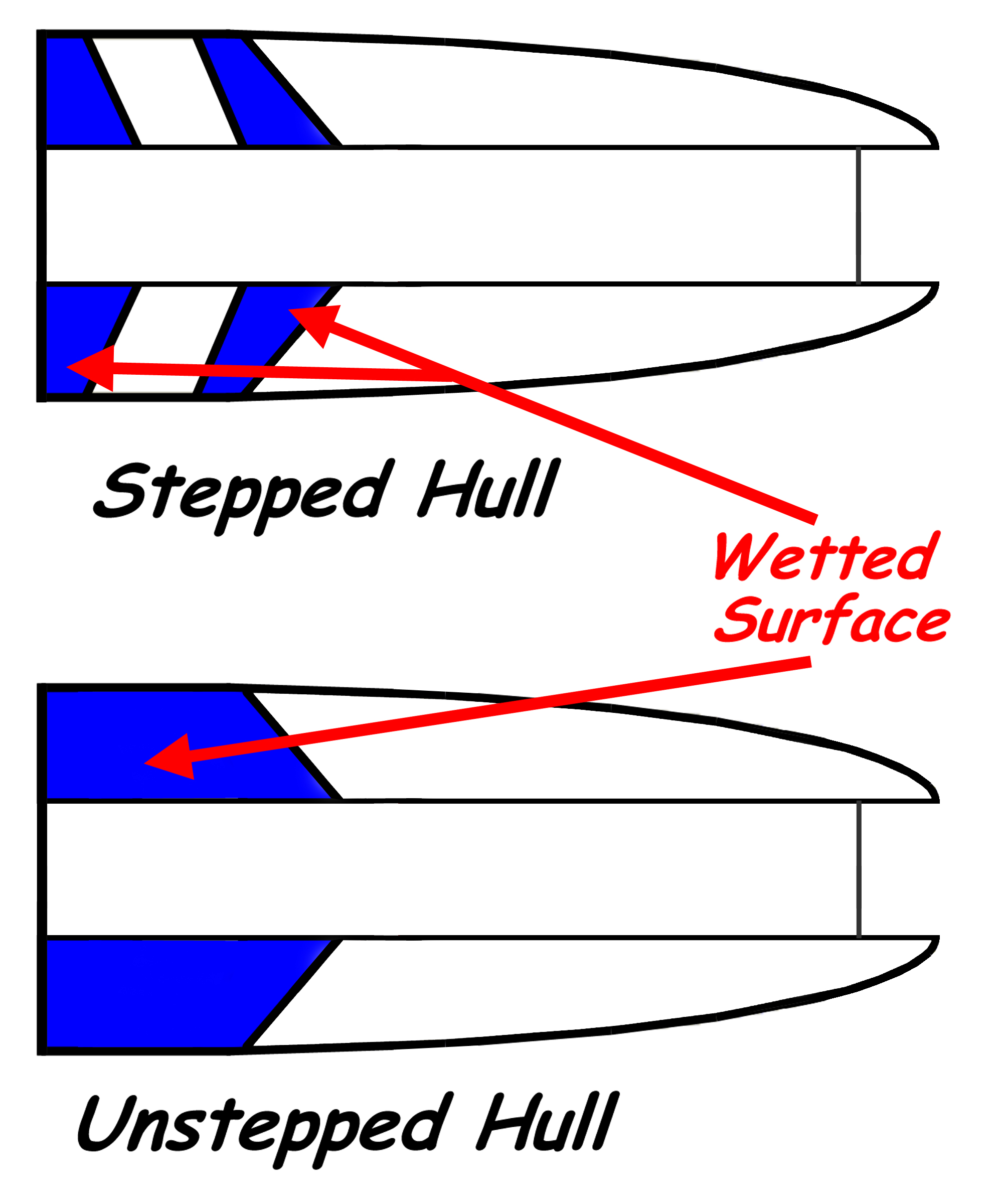

Here's How It Works

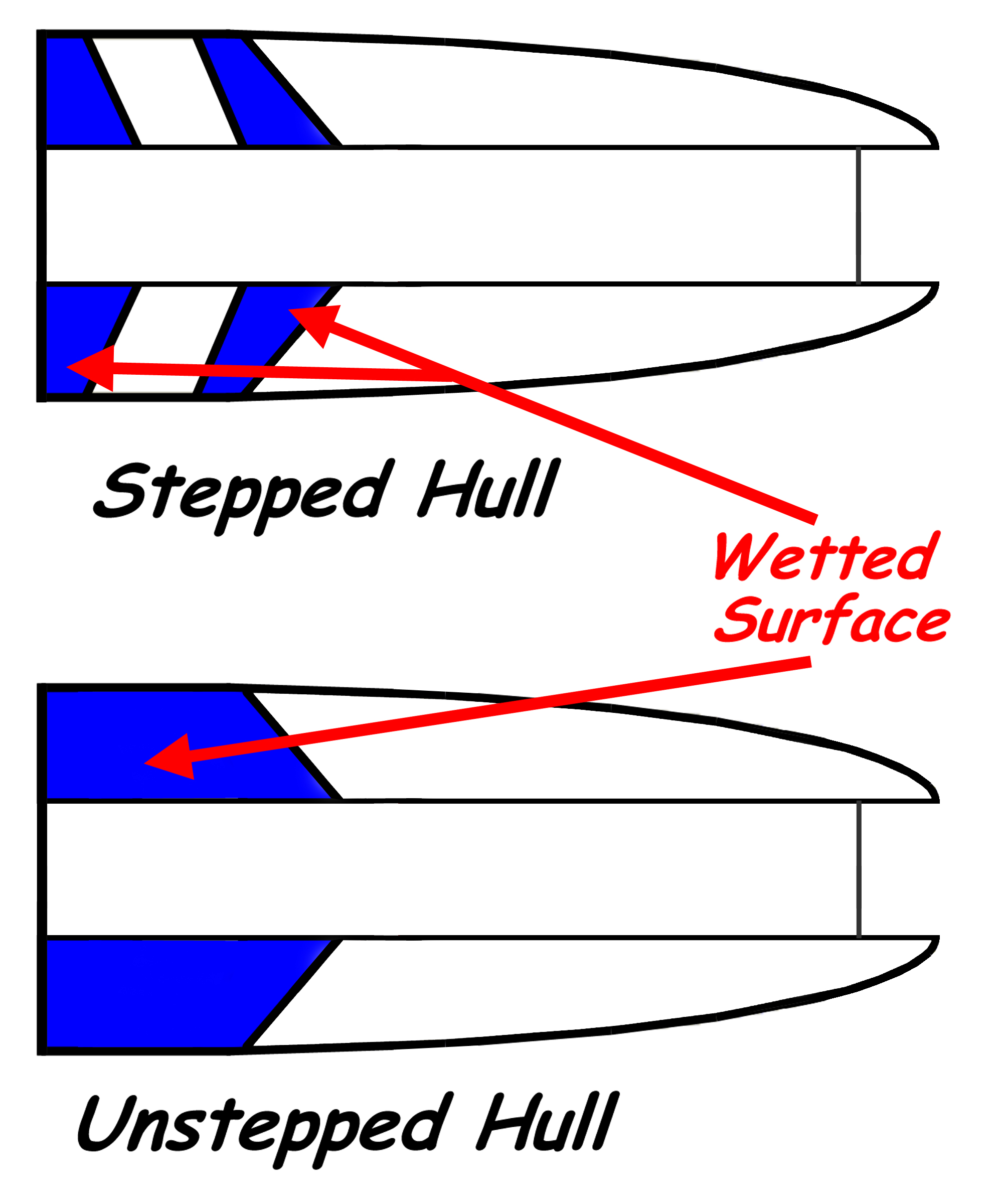

The

hydrodynamic Lift generated by planing surfaces is influenced, in part, by

the surface area, aspect ratio, and trim angle of the wetted surface(s).

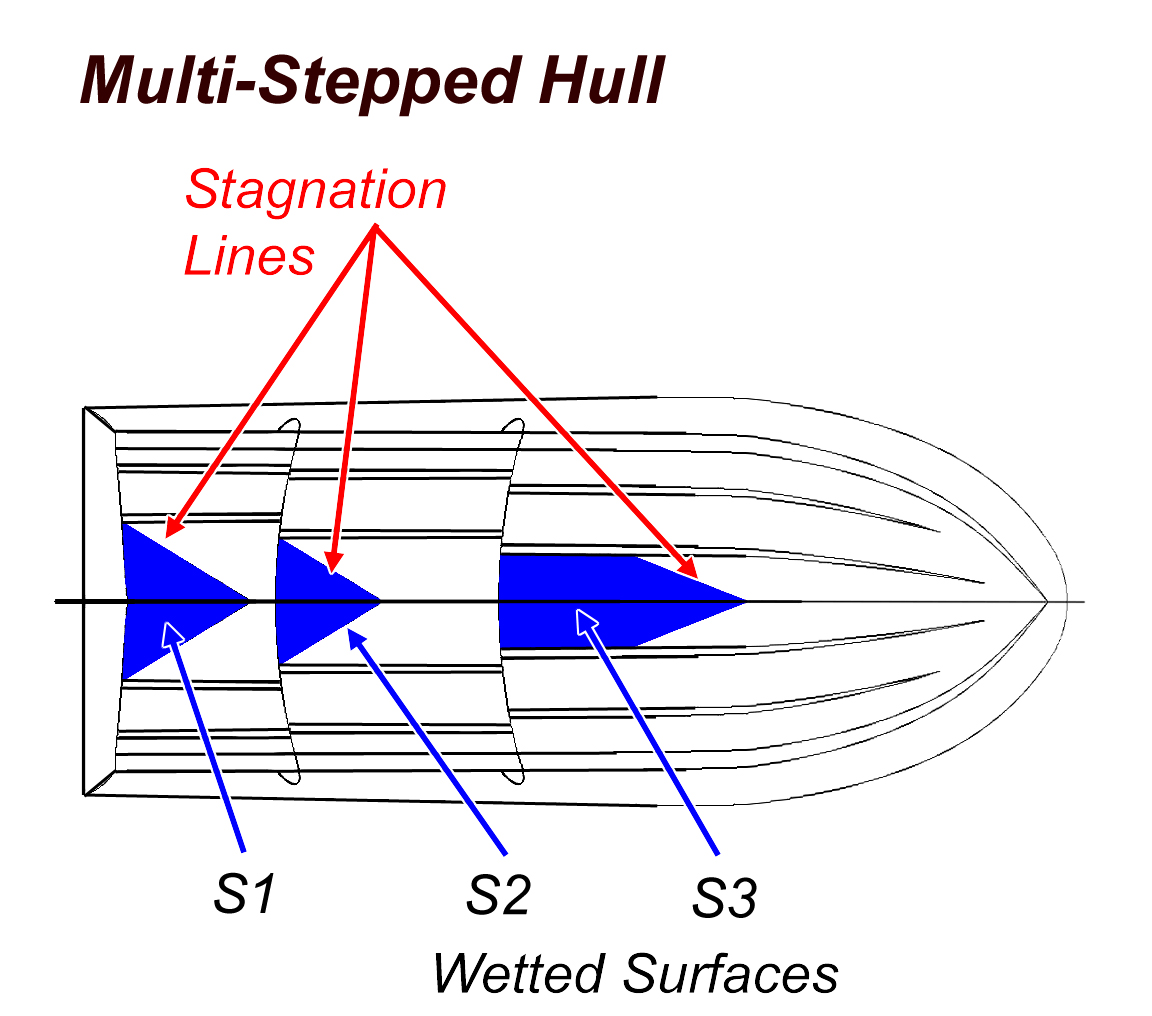

In the case of a stepped hull design (say 2 steps), there can be 3

separated wetted surfaces. If effectively designed, these 3 separate

lifting surfaces can be more efficient than the single surface that a

non-stepped hull could deliver.

The

step design imposes a set angle of attack for the planing surface area aft

of the step. This 'step angle' incrementally increases the total

'trim angle' that the planing surfaces see (hull trim angle + step angle =

total 'planing trim angle'). Higher trim angle generates more lift.

At the same time, the 'Aspect Ratio'

(width/length ratio of the planing surface) for each of the 3 lifting

surfaces of the 2-step hull are greater and so contribute to more

efficient lift (more lift, less drag) than the shape of a longer, single

(non-stepped) planing surface.

Finally, the imposed 'step angle' helps

maintain a minimum angle of attack for the surfaces that, if properly

designed, can optimize the lifting efficiency (L/D) of each surface. Any change in trim angle affects each of the 3 planing surfaces - which

also changes the wetted surface and AR too, and thus affects the Lift &

Drag generated by each of the 3 surfaces. So the performance

analysis of step design is quite complex. Overall, however, there

are benefits of the application of steps to a hull design. [TBDP©/VBDP© can

do all of the engineering performance analysis to optimize effective multi

step design].

Contributors to Step

Design/Performance

Hydrodynamic forces and effective lifting

surface shapes, areas and attack angles at each individual

step surface must be calculated, based on key contributors and local

conditions throughout the entire operating velocity range:

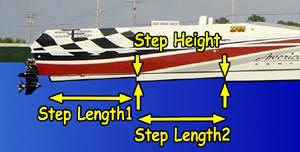

- Step Length

- Step Height

- Step Angle (Τ)

- Surface Deadrise angle (β) at local step

- Trim Angle (α) at local step

- Planing surface configuration forward of step

Step Performance can be determined based

on:

- Lift force at each local step

- Drag at each local step

- Whisker spray drag at each local step

- Unwetted void length aft of forward step

- Wetted width (bwidth) at local

step

- Wetted Length (LWetStep)

- Centre of Pressure of local step lifting

force

- Hull trim angle

(αh)

Step forces can influence hull performance as:

- Total Wetted suface

- Total Wetted length

- Centre of Dynamic Lift wrt CG

- Effective trim angle (αe)

- Porpoising onset velocity

- Effective CL, CD, CP

- Effective Aspect Ratio (ARstep)

- Dynamic Stability

- Dynamic Centre of Forces (XCFDynamic)

Issues with Steps

The most significant issue with step design is the engineering challenge

of properly locating an efficient step on the hull. The length of planing

surface behind the step (i.e.: the location of the step) and depth of the

step have an impact on the performance of the setup. Designing the step

improperly can actually decrease performance. The issue of multiple steps

makes the challenge even trickier. So, it is critical to have a

defined understanding of how much

effective lift that a stepped planing surface will generate and

at what (longitudinal) location each

stepped planing surface will be acting.

Some designers stay away from

including steps in designs because of degradation in performance at low

and moderate speed range. At lower speeds the steps are entirely

immersed, so each step actually adds drag to the hull. At moderate speeds

during the transition to full planing, air must get back behind the steps

or the boat will suffer the penalty of continuing high drag. So the step

is really only ideally functional at its single design velocity, and thus,

it can potentially generate a penalty at all other velocities. Use of

ventilating steps by design can cause the hull to "trip" on the irregular

chines causing a dangerous stability problem with serious handling

results.

Complex Step

Performance Analysis

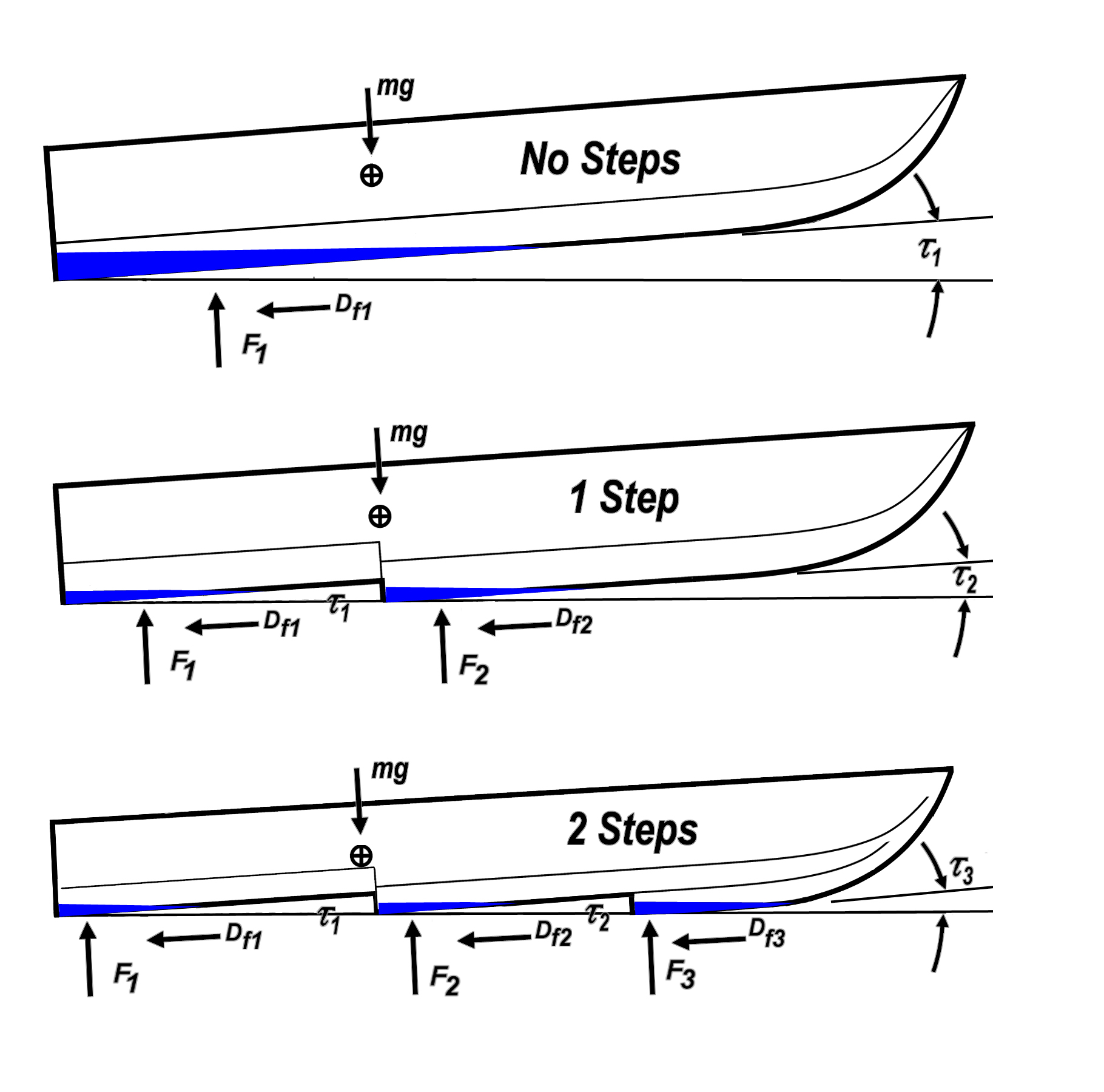

Although the geometry of stepped hull

lifting surfaces is extrememly complex, the multiple lifting surfaces can

generate more efficient Lift and Drag due to higher Aspect Ratio of multiple

surfaces for same wetted surface. Most importantly, the location of Dynamic

CG of stepped surfaces is shown to be foreward of non-stepped surfaces,

improving Dynamic Stability in key regions of velocity range. Instead of a

single longer non-stepped wetted length, stepped planing surfaces are

shorter (thus higher Aspect Ratio for similar planing width, (bplaning) separated by

aerated (non-wetted) surfaces. While complex to calculate, these multiple

surfaces can be more efficient and can move CGDynamic further forward,

improving Dynamic Stability.

As trim angle changes, each stepped planing surface can

change it's wetted length and thus, the lift force generated. It is

possible (frequent) that a forward stepped planing surface can become

fully un-wetted at a specified velocity and particular trim angle.

This scenario can significantly change the magnitudes and longitudinal

location of hydrodynamic lift forces, and thus Dynamic Stability

characteristics of the hull. Step Loading (lift force/load at each lifting

step location) is key to understand and balance with other active forces,

for dynamic balance throughout velocity range.

Step performance is influenced by the wetted length of the aft-step

surfaces. This length is influenced by many factors, including hull

trim angle (αh), effective (step) trim angle

(αe), and the reattachment point of water flow

as it flows from forward step to aft-step surfaces. All of these

characteristics must be accurately accounted for when determining the

performance and dynamic stability of step designs.

Variable deadrise hull bottoms sould be carefully considered

when employed with steps.

The local deadrise angle (β) at step locations influences lift

coeficient and thus local lift and step loading balance. Flatter

sections of a stepped hull can overpower the deeper forward sections, and

force the bow down at speed. It's preferable to keep local deadrise at

multiple steps similar to avoid step loading balance and dynamic stability

issues.

TBDP©/VBDP©

provides

a step analysis report for the full operating velocity

range that includes the trim angle, dynamic stablity, changing wetted

lengths for each step(s) section - even highlighting the velocity at which each

of your steps become fully 'unwetted' (or not).

Location

of lift forces from each stepped planing surface are calculated and used

to generate total hydrodynamic lift force map for performance analysis

including dynamic stabliity. This analysis allows us to show when

your steps are effective and at what velocity the steps become most effective. Comparative/optimizing analysis is provided by changing step

designs and graphically comparing results of different design

alternatives. |

|

|

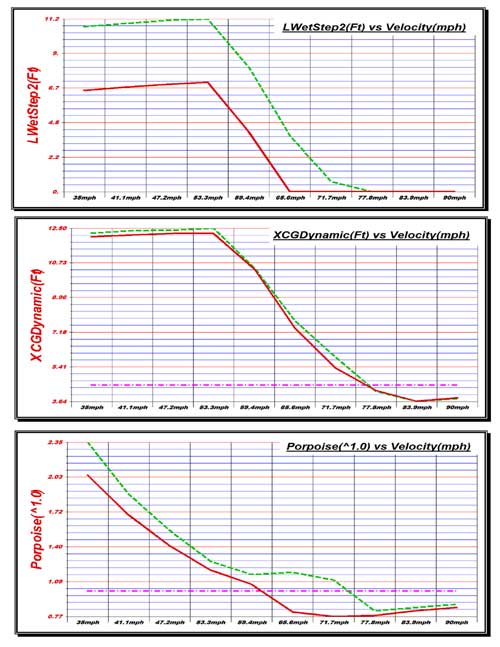

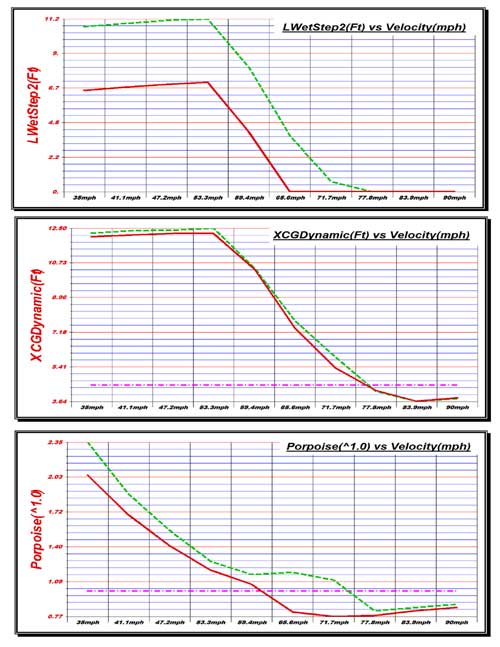

'Steps Performance

Analysis' including step wetted length, dynamic stability, and

porpoise analysis graphs [excerpt TBDP/VBDP, comparison of two alternative

step designs; 3 of graphs] |

Step Height and

Step Angle

A properly designed step can help maintain a

constant trim angle (WAngle), reducing cyclic changing trim angles under

operating conditions. Step Height and Step Length set the Step Angle, for

each step design. A designer can design the step height and step

angle to optimize the planing trim angle of the planing surface(s). A step

height that is too large can impose a step angle that is too high, causing

additional drag and, more importantly, resulting in very low hull trim

angles (even WAngle=0), exposing other surfaces to increased wetting and

extra drag under many conditions. Step height should be considered so that

step angle does not result in very low operating WAngles. A reasonable guideline

is a step angle of less than 1/2 of optimum trim angle (example, if

optimum trim angle = 4 degrees, then max step angle could be set to less

than 2 degrees).

TBDP©/VBDP©

performance Reports provide analysis of step design, reporting for Optimum

Step Height(s) and Optimum Step Angle(s), and recommendations for Step

location, step height and step angles, as well as leading planing surface

design (foreward of step surfaces).

Multiple Steps

There are additional challenges with multiple steps.

1) If the steps

are located too close to each other, the water attaching to the second

step is "contaminated" by aerated low-density water from the first step,

so the aft step does not produce the high lift forces desired.

2)

Where do we locate the center of weight (LCofG) so that the weight is

balanced across the steps? Remember, the running trim angle can change

throughout the speed range and this makes a huge difference in the

lift-force distribution on your steps. It takes only a small change in

the relative locations of the CofG to change your boat from a stable,

efficient boat to one that porpoises at several velocities.

[TBDP©/VBDP©

performance design software helps to optimize step design and

placement, and provides performance analysis of any hull with or without

steps.].

|